Связано: Типы главных шпинделей - какой лучше для вашего станка с ЧПУ?

В мире, где все хотят получить товар немедленно, когда каждый живет по известной норме ОДНОГО КЛИКА для получения заказа на следующий день напрямую из любой точки земли... станки с ЧПУ бесценны. Без главного шпинделя строительство станков с ЧПУ невозможно, поскольку это сердце каждой машины, где обрабатываются точные параметры резки и формовки. Выберите лучший шпиндель и получите максимальную производительность и эффективность.

Сегодня на рынке можно найти несколько ведущих брендов для главных шпинделей станков с ЧПУ, таких как HSD, Colombo, Perske и Omlat — крупные имена на рынке, которые выделяются качеством своих основных продуктов.

От принятия решения о том, сколько мощности вам нужно для каждого пропила, до обеспечения правильной скорости вала и достижения точности на вашем заготовке. Кроме того, тип материала, с которым вы работаете, и какие операции обработки необходимо выполнить, поможет сузить ваши предпочтения. Учитывая эти моменты, вы можете сделать оптимальный выбор моторного вала для максимизации производительности при обработке.

Как я уже упоминал ранее, эта задача выбора правильного шпинделя может быть немного подавляющей для новичков в области ЧПУ. Чтобы принять обоснованное решение, необходимо учитывать несколько самых важных вещей: полное рассмотрение бизнеса офлайн- versus онлайн-магазинов, ключевые факторы перед выбором между ними:

Мощность обработки - Это резательная сила, создаваемая шпинделем.

Точность изделия: Насколько надежен шпиндель при выполнении точного реза или формирования желаемой формы

Инструмент номер один: Бруклинский подход - Материалы шпинделя снова предоставляют различные материалы, на этот раз фокусируясь на том, что будет наиболее безопасным для ваших свитеров.

Тип фрезерования: Шпиндель используется в этом процессе обработки.

Все эти факторы делают это идеальным электрическим шпинделем для ваших обрабатывающих операций, и использование их может помочь вам оптимизировать производственные процессы в нашем рекомендуемом электрическом шпинделе.

Как продлить срок службы вашего электрического шпинделя

Теперь, когда мы перечислили характеристики электрических шпинделей, важно поддерживать их в хорошем состоянии и проводить регулярное обслуживание для длительной эксплуатации и надежного обслуживания. СОХРАНЕНИЕ ВАШЕГО ШПИНДЕЛЯ - РЕКОМЕНДАЦИИ ПО ПРОДЛЕНИЮ СРОКА СЛУЖБЫ

Общее правило: если вы обнаружите значительное количество пыли и грязи в пространстве вокруг, оно будет довольно быстро загрязняться.

Смазка: смазку следует использовать согласно рекомендациям производителя. Несоответствие требуемым типам смазки может привести к быстрому износу деталей шпинделя и дорогим последствиям.

Проверьте и установите натяжение ремня шпинделя: за этим нужно следить и, возможно, регулярно регулировать для его поддержания.

Позиционирование XY: Это указывает на точность вашей CNC-машины и требует проверки на наличие механических ошибок, чтобы получить безупречную строчку в готовом продукте.

Регулярные проверки: Осматривайте каждый день, если вы начнете замечать признаки проблем, исправьте их до того, как они ухудшатся!

Таким образом, срок службы двигателя вашего шпиндельного CNC-станка увеличится, а также сохранится его производительность со временем.

Технологические достижения и все будущие разработки для шпиндельных двигателей CNC: Прогресс и развитие, на которые стоит обратить внимание в будущем, включают:

Внедрение: Показывает использование аналитики данных и методов IoT для мониторинга и улучшения работы шпинделя в соответствии с принципами Индустрии 4.0, как обозначено в рамках Четвертой промышленной революции в условиях производства с высокой точностью.

Умные шпиндели: Интеграция датчиков и аналитики внутри шпинделя для предоставления предварительного оповещения о несоответствиях в работе шпинделя.

Металлическая печать: 3D-печать для исследований возможных применений шпиндельных двигателей CNC.

Гибридные станки: Дальнейшее развитие гибридных станков, которые позволяют как фрезеровку, так и добавление материалов для двойной функциональности.

В ближайшие годы дальнейшее развитие моторизированных шпиндельных ЧПУ выведет эту и другие технологии далеко за пределы их текущих возможностей.

При должном уходе даже моторизованные шпиндели ЧПУ могут сталкиваться с временными проблемами CAN. Следующие профессиональные советы помогут вам их решить:

Шатун шпинделя — это может быть вызвано неправильным натяжением ремня шпинделя или изношенными подшипниками

Вибрация — проверьте чрезмерную вибрацию, которая может быть результатом ослабленных шпинделей или несбалансированного инструмента; исправьте проблему.

Не допускайте перегрева: Регулярно проверяйте системы охлаждения, так как это важный элемент, который также может вызвать перегрев вашего РВ, и помните о правильной смазке.

Ошибки в программировании: Перезапись программы и исправление ошибок, когда невозможно правильно выполнять обработку.

Способ решения промежуточных проблем может упростить поиск решений и гарантировать, что производительность остается на самом высоком уровне, именно так следует проводить диагностику электродвигателя в ЧПУ согласно экспертным мнениям.

Обладая более чем десятилетним опытом ведения бизнеса, компания SWFIT пользуется хорошей репутацией среди клиентов как в Китае, так и за рубежом. Мы ценим каждого клиента и внимательно относимся к его потребностям. Наша цель — обеспечить клиентам высококачественные шпиндели для станков с ЧПУ и выстроить взаимовыгодные отношения.

Компания SWIFT модернизировала производственные мощности по обработке и сборке шпинделей для станков с ЧПУ: на предприятиях установлены передовые импортные станки — универсальный круглошлифовальный станок STUDER, плоскошлифовальный станок OKAMOTO, вертикальный шлифовальный станок TAIYO KOK, токарно-обрабатывающий центр DOOSAN, координатно-измерительная машина ZEISS, а также профилометры и формы-измерители MAHR. Применение новейших технологий и сертификация по стандарту ISO 9001 гарантируют клиентам получение продукции высочайшего качества в любое время.

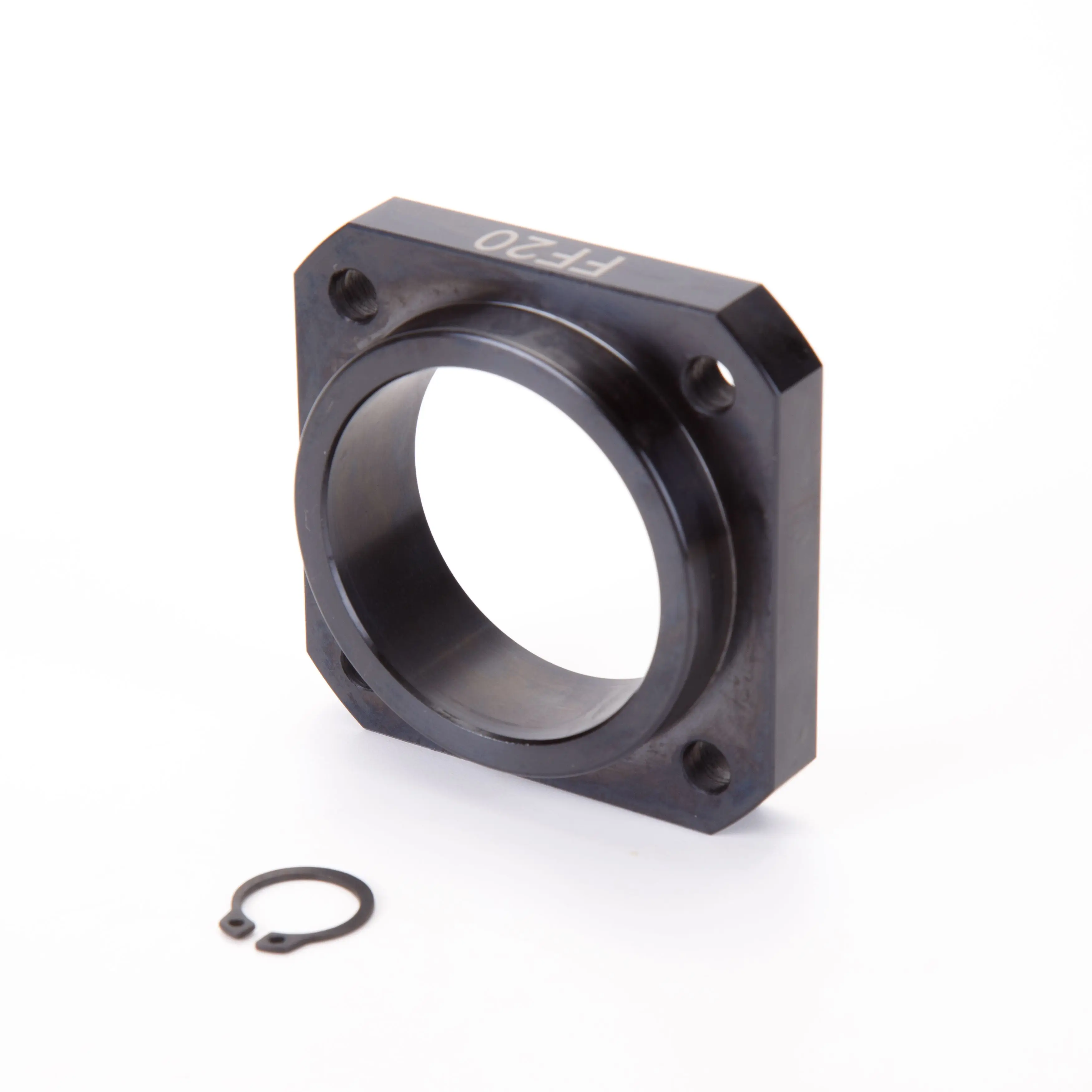

Компания Jiangsu Swift Machinery Technology Co., Ltd была основана в 2011 году и специализируется на разработке, производстве и продаже прецизионных компонентов для станков с числовым программным управлением. Продукция Swift включает высокоточные стопорные гайки, опорные узлы для лёгких и тяжёлых нагрузок, ременные и прямые приводы, электродвигатели-шпиндели, а также множество других высокоточных компонентов. Мы выпускаем электродвигатели-шпиндели для станков с ЧПУ в стандартных моделях, а также разрабатываем и изготавливаем их по требованиям наших заказчиков.

От сырьевого мотор-шпинделя с ЧПУ до конечных продуктов все производственные процессы осуществляются на заводе SWIFT. Это гарантирует быструю доставку, высокое качество и конкурентоспособные цены на продукцию SWIFT. Благодаря постоянным усилиям нашей команды исследований и разработок, инновационные идеи и технологии используются для оптимизации и улучшения существующих продуктов и повышения эффективности продукции.

Авторские права © Jiangsu Swift Machinery Technology Co., Ltd. Все права защищены - Политика конфиденциальности