Thread tapping, which is a process that entails inserting threads in a hole. Thread Milling: A cutting tool makes internal threads. Therefore, when thread tapping takes place the spindles with taps must be used as they assure quality and quick forming of these threads. Uniquely, it is fast tap for close-to-size threads.

However, while operating a tapping spindle, the choice of tap size and speed is also most important. Furthermore, upon considering the hole dimensions and type of materials to be tapped on will determine the size of tap and speed respectively. It’s important to keep the spindle orientation perpendicular to the workpiece surface so that any thread-tapping errors can be avoided.

Right before tap just like in pre-lubrication stages, use this lubricant too. It will mitigate frictional force and heat that are usually generated during tapping operation. On one hand if cutting becomes uncontrolled then chipping occurs on tools leading to unevenness of thread patterns. On the other hand, proper greasing ensures long life span for your tools through better threading.

The guarantee here is accuracy in threading coupled with increased productivity because you have put in place such an accurate system making use of a tapping spindle. One way to help cycle times is by using a high-speed tapping spindle. The SWT motor spindle will facilitate slant providing ways to high-speed largest screw cutting.

Ridgway added that “Multi-spindle tapping heads can increase outputs as well so it’s another way you can get more power into it.” Consequently, introducing multiple spindles simultaneously reduces total cycle time hence improving efficiency. Again, this multi-spindle has an advantage at this point-multiple holes tapped simultaneously.

Tapping spindle Get more out of your manufacturing operations. For example this increases productivity significantly and not just in terms of tapping time; it is also a case where more than one hole is tapped at ago. Hence, the other process that can be done on tap spindles are for carefully determined and very accurate threads unlike when a person threads this same thread with his or her hand which is highly labor demanding.

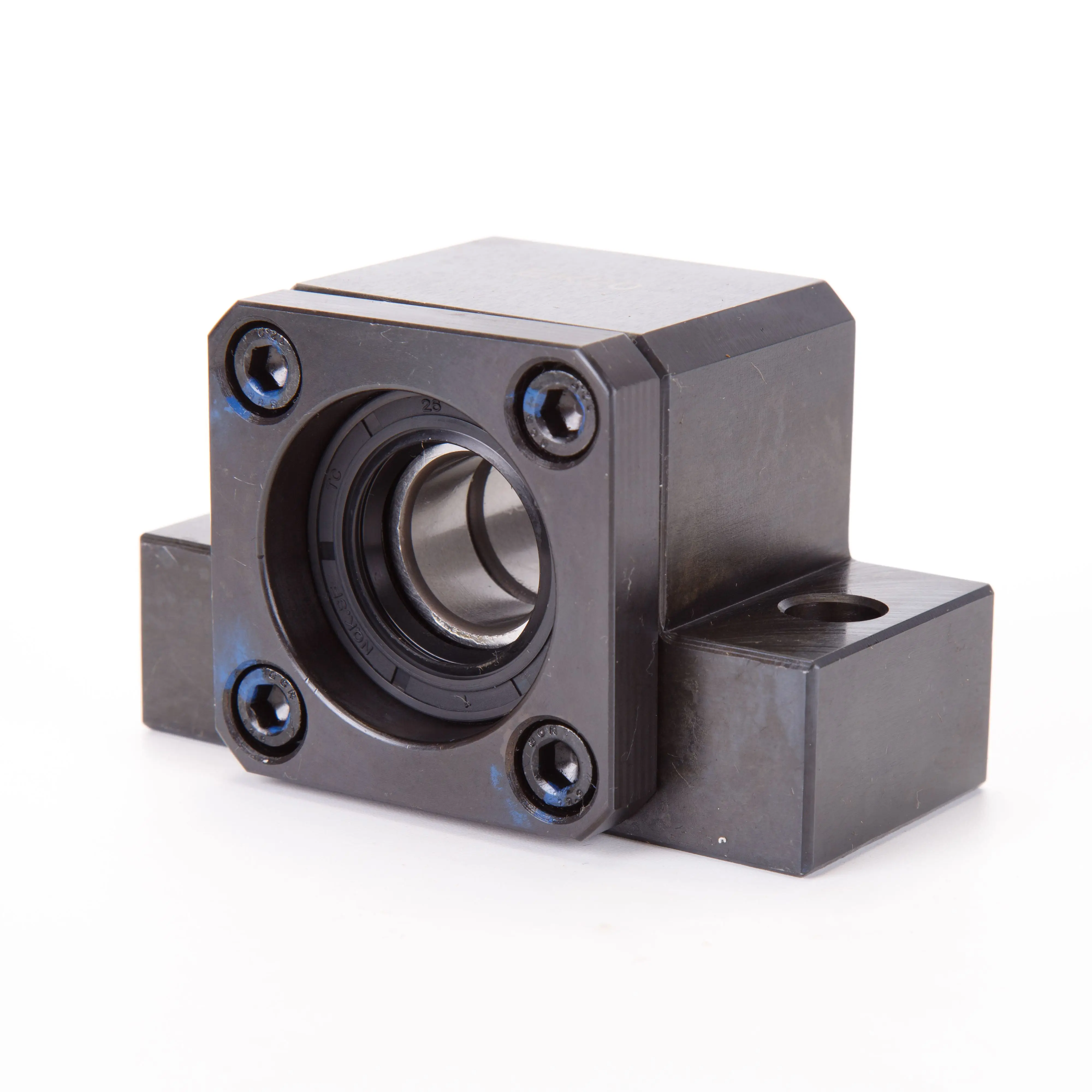

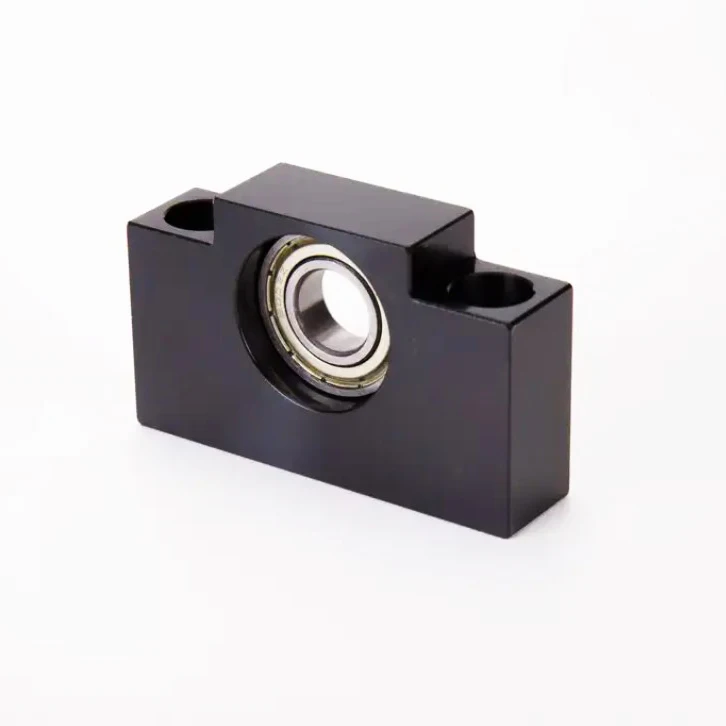

One of the advantages of using a tapping spindle is that you can prolong your tool life. SWT machine spindles ensure a longer life for the tapping tool by means of a specially-designed lubricating system and spindle bearing maintenance. Furthermore, these new advanced machines do not cause repetition strain injuries like manual threading does because they even have safety measures such as special thread taps to prevent operator fatigue.

Then you do the right methods in using it and maintenance, but sometimes there are still problems around with tapping spindles that can be detrimental to your tap. One common problem which happens mainly due to incorrect size of tap speed and dimensional lapses in tap tooling is breaking of tools while in operation. The right choice should therefore be made as regards the size and speed as far as this material is concerned so as to prevent breakage during operation.

Material tools in the subsequent generations of thread deformation, chipping or other means damage. Wear mechanical with worn or damaged tread Make sure to re-tapping this tool and position on turning by one way closing condition as thickness for wearable.

Tread wear mechanical with worn out or damaged tread Re-tap this tool with a closing condition of turning it by a thickness that can be used as a wearable.

Excessive damage to tapping spindles can cause overheating, resulting into inaccurate tap threads hence reducing the life of the tool. The main cause of overheating is lack of less lubrication as well as overusing tools way beyond their life. With enough lubrication and not feeding it too got worn tools, you can avoid that. With enough lubrication and not utilizing highly worn-out taps avoid that.

However, the choice of suitable tapping spindle depends on how you manipulate your material and what kind bore are we working with. The high-speed tapping spindles are best suited for fast-tapping applications like in the case of Inconels and other materials that are difficult to machine, while multi-spindle tapping heads provide unparalleled performance given their capabilities when it comes to threading multiple holes at once. Best option for the finer threads is a comparable reliable and accurate tapping spindle with confirmed-dimensional precision as well with high-quality threading mechanism. This taps the SWT machine tool spindle while ensuring that it is set to start, guaranteeing a properly optimized and reliable threading operation.

Thus, a tapping spindle is an indispensable necessity at any manufacturer looking to cut perfect threads fast and turn things up that extra notch with their machining productivity. It is vital to observe good usage and maintenance practices in order for the correct tapping spindle service life, optimum efficiency and/ or better performance values are achieved.

Jiangsu Swift Machinery Technology Co., Ltd was founded in year 2011 and is specialized in development, production and sale of precision components used numerical-control machine tools. Swift's products include high-precision lock nuts, support units both light and heavy loads, belt drive and direct drives, motor spindles many other components that are high-precision. We Tapping spindleregular models as well as create and manufacture according to requirements of our customers.

With over ten years expertise in field, SWFIT has good Tapping spindleamong customers in China across the globe. We are devoted to every customer and place high value on the needs of each customer. Our customers the core of our business. We strive achieve win-win collaboration.

From raw Tapping spindleto final products, all manufacturing procedures implemented within SWIFT factory. guarantees quick delivery, top quality and competitive prices SWIFT products.With the ongoing efforts of our Research Developing team, innovative ideas and technology utilized to optimize and improve the existing products and improve the efficiency of products and efficient.

SWIFT has modernized temperature-controlled machining assembly workshops and has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. customers assured receiving reliable products throughout day because Tapping spindledevices and ISO9001 certification.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy