Vai trò của Bu-lông Căng Chính Xác trong Máy Móc

Bu lông khóa chính xác là một thành phần thiết yếu đảm bảo sự vận hành trơn tru và chính xác của bất kỳ máy móc nào. Những bu lông này được chế tạo với mục đích ngăn chặn các vòng bi di chuyển như đã thiết kế, vì vậy trong các hoạt động tốc độ cao, chúng sẽ không bị dịch chuyển hoặc lỏng lẻo. Lần này, chúng ta sẽ thảo luận về các ưu điểm khác nhau khiến bu lông khóa chính xác trong máy móc trở nên vô cùng quý giá đối với chúng ta, đánh giá tầm quan trọng của chúng khi nói đến các hoạt động tốc độ cao và xem qua các bước chính để chọn bu lông phù hợp cho công việc của bạn cũng như một số mẹo hữu ích về cách sử dụng chúng.

Những Ưu Điểm Của Bu Lông Khóa Chính Xác Cho Máy Móc

Bu lông khóa nặng chính xác có nhiều lợi ích để cung cấp;

Độ Chính Xác Cao: Bu lông khóa chính xác cũng đảm bảo độ chính xác trong việc siết chặt các bộ phận cơ khí, loại bỏ mọi khả năng xảy ra lỗi trong quá trình vận hành máy móc.

Đảm Bảo Độ Bền: Những bu lông này ổn định máy móc một cách dễ dàng và không cho phép lỏng lẻo hoặc hiện tượng giật lùi trong quá trình vận hành.

Tăng tuổi thọ: Bu-lông khóa chính xác ngăn ngừa các bộ phận bị lỏng, giảm mòn và tăng tổng thể tuổi thọ của thiết bị.

Nó cung cấp một cách hiệu quả về chi phí để đảm bảo công việc máy móc được thực hiện trơn tru và chính xác, ngăn ngừa thiệt hại tốn kém có thể xảy ra do bu-lông bị lỏng (hoặc hiện tượng hồi lực).

Tại sao Bu-lông Khóa Chính Xác Lại Quan Trọng Trong Ứng Dụng Tốc Độ Cao

Bu-lông khóa là không thể thiếu cho các ứng dụng tốc độ cao: nếu có bất kỳ chuyển động thời gian hoặc nhiệt, nó phải được kiểm soát nếu không sẽ xuất hiện sai lệch giữa các bộ phận và thiết bị có thể bị hư hỏng với rủi ro an toàn tiềm ẩn. Các hoạt động tốc độ cao nghĩa là các bộ phận bị ảnh hưởng bởi lực di chuyển ở tốc độ chóng mặt, dễ dàng khiến các bộ phận trượt và mất cân bằng, hoặc tệ hơn là độ chính xác. Để giữ các bộ phận chắc chắn trong vị trí và cung cấp hoạt động làm việc an toàn, chính xác, cần sử dụng bu-lông khóa chính xác.

Điều này có nghĩa là việc chọn bu-lông khóa chính xác có thể khiến bạn cảm thấy choáng ngợp do sự đa dạng của chúng. Dưới đây là những điều quan trọng nhất để giúp bạn lựa chọn.

Vật liệu của bulong là gì? Sử dụng cấp độ phù hợp từ điều kiện môi trường nơi mà chi tiết công việc của bạn sẽ được sử dụng.

Kết thúc lựa chọn - Hãy chắc chắn rằng bạn chọn đúng loại đầu cho ứng dụng mong muốn của dây hoặc kích thước sợi vít hoặc trục.

Hỗ trợ nhiều phương pháp thiết kế khác nhau để chọn một giải pháp phù hợp cho dự án của bạn.

Kiểm tra giới hạn tải: Chọn một bulông có thể chịu được loại tải mà bạn sẽ sử dụng nó cho mục đích đó.

Đảm bảo Tương thích: Hãy chắc chắn rằng bulông khóa chính xác mà bạn chọn có thể được sử dụng dễ dàng và hiệu quả với tất cả các thành phần cơ khí khác của bạn.

Khi nói đến dự án của bạn, bulông khóa chính xác hoàn hảo sẽ phụ thuộc vào các yêu cầu ứng dụng độc đáo bao gồm khả năng chịu tải, điều kiện môi trường và sự tương thích của các thành phần. Tham khảo ý kiến từ nhà cung cấp bulông khóa chính xác có thể giúp bạn chọn đúng loại cho bất kỳ dự án nào.

Dưới đây là một số mẹo thực tế giúp tăng khả năng sử dụng bulông khóa chính xác.

Trước khi lắp đặt: Trước khi lắp bulong khóa, hãy đảm bảo rằng ren bu lông hoặc trục sạch sẽ và không có tạp chất.

Các bước siết chặt đúng cách: Sử dụng giá trị lực siết đúng khi siết chặt bulong khóa để đạt được tải kẹp cần thiết.

Sử dụng Cờ-lê Siết Lực: Những công cụ này được thiết kế đặc biệt để áp dụng lực siết một cách chính xác.

Không Siết Quá Chặt: Đây là điều quan trọng cuối cùng cần luôn小心 không siết quá chặt bulong khóa, điều này có thể gây hư hại cho các bộ phận và làm giảm tuổi thọ.

Kiểm Tra Thường Xuyên: Kiểm tra bulong khóa và đảm bảo nó được cố định (ví dụ như chịu rung động cao, siết lại).

Chúng được ứng dụng trong máy móc, nơi chúng phải hoạt động như thành phần quan trọng không chỉ cung cấp độ chính xác mà còn cả sự ổn định, tiện lợi và tuổi thọ, tất cả đều dẫn đến hiệu quả về chi phí. Điều này đặc biệt quan trọng đối với các ứng dụng tốc độ cao, nơi thời gian và an toàn là yếu tố then chốt. Cách Chọn Bu-lông Căng Chính Xác Phù Hợp Bạn cần chú ý đến các yếu tố như vật liệu, kích thước, thiết kế, khả năng chịu tải và tính tương thích khi chọn bu-lông căng chính xác. Thực Hiện Các Mẹo và Đề Xuất Này để Tối Ưu Hóa Máy Móc của Bạn Với Bu-lông Căng Chính Xác

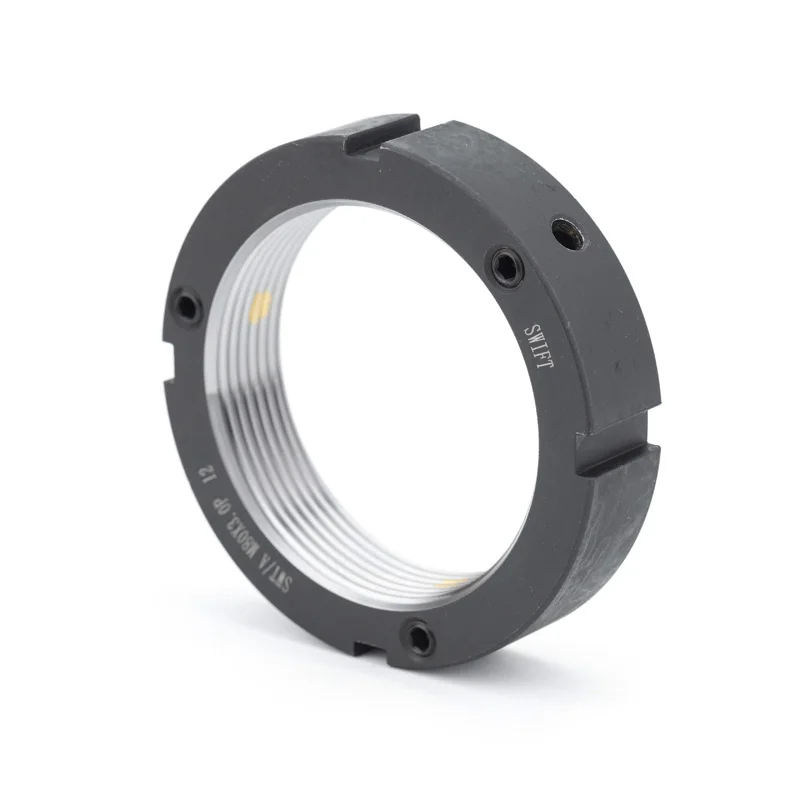

Công ty TNHH Công nghệ Máy móc Swift Giang Tô được thành lập vào năm 2011 và chuyên về phát triển, sản xuất và bán các linh kiện chính xác được sử dụng trong máy công cụ điều khiển số. Các sản phẩm của Swift bao gồm đai ốc khóa độ chính xác cao, đơn vị hỗ trợ cả tải nhẹ và nặng, hệ thống truyền dây đai và truyền trực tiếp, trục động cơ cùng nhiều linh kiện khác có độ chính xác cao. Chúng tôi cung cấp các mẫu đai ốc khóa chính xác thông thường cũng như thiết kế và sản xuất theo yêu cầu của khách hàng.

Với hơn một thập kỷ kinh nghiệm trong ngành, SWFIT đã xây dựng được danh tiếng tốt với khách hàng từ Trung Quốc và trên toàn thế giới. Đai ốc siết chính xác — mỗi khách hàng đều được quan tâm kỹ lưỡng theo yêu cầu riêng của họ. Đặt khách hàng lên hàng đầu để đạt được sự hợp tác cùng có lợi.

SWIFT đã hiện đại hóa xưởng lắp ráp bu-lông khóa chính xác điều khiển nhiệt độ, đã nhập khẩu máy mài universal STUDER hàng đầu, máy mài bề mặt OKAMOTO, máy mài đứng TAIYO KOK, trung tâm gia công CNC DOOSAN, máy đo tọa độ ZEISS CMM, thiết bị đo hình dạng MAHR. Thiết bị tiên tiến chứng nhận ISO9001 đảm bảo rằng khách hàng của chúng tôi sẽ nhận được sản phẩm đáng tin cậy mọi lúc.

Từ nguyên vật liệu đến sản phẩm hoàn chỉnh, toàn bộ quy trình sản xuất đều được thực hiện tại nhà máy SWIFT. Đai ốc siết chính xác — giao hàng nhanh, chất lượng vượt trội và giá cả cạnh tranh cho các sản phẩm của SWIFT. Nhờ những nỗ lực không ngừng của đội ngũ Nghiên cứu và Phát triển, các công nghệ và khái niệm mới liên tục được áp dụng nhằm tối ưu hóa và cải tiến các sản phẩm hiện có, đồng thời nâng cao hiệu suất và tính hiệu quả của sản phẩm.

Bản quyền © Công ty Công nghệ Máy móc Giang Tô Swift. Tất cả các quyền được bảo lưu - Chính sách bảo mật