Why are hydraulic lock nuts indispensable in the case of industrial settings like factories and construction sites into consideration? Bolts they help prevent bolts unsafe even when subjected to shock loading or vibration, variables load temperatures and conditions. Unlike conventional nuts, these need to be tightened against the bolt using a special hydraulic system that keeps them in place preventing their come unloose even under the toughest conditions.

For machines, it can also use hydraulic lock nuts to facilitate SWT maintenance. This mostly necessitates the usage of standard bolts that still need to be tight in each and every time which is another extra task which consumes a lot of your time. How to Avoid Constant Tightening Hydraulic lock nuts can stop the constant tightening. Such nuts come with the ability to lock themselves into position so that no frequent adjustment is required. They also simplify disassembly inspections/repairs without damage.

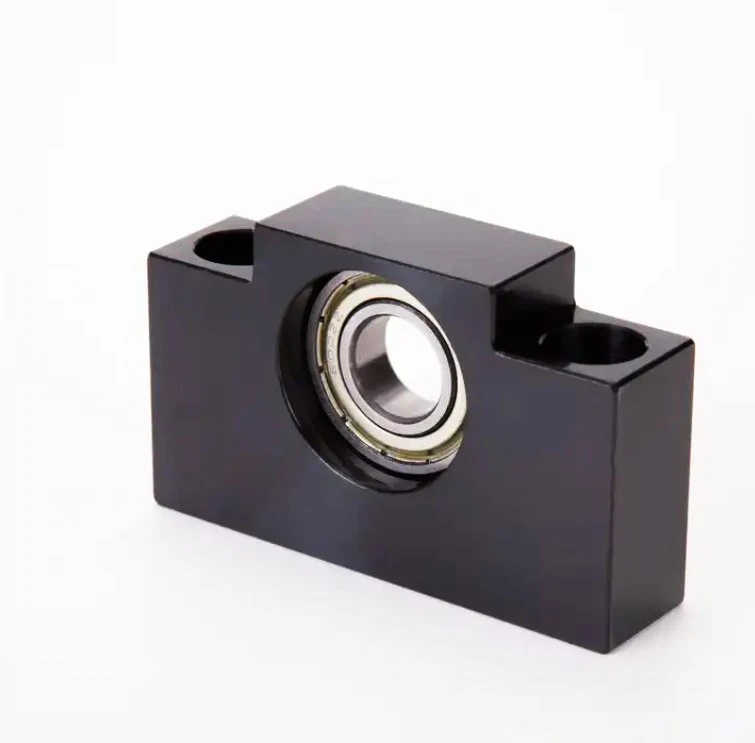

A hydraulic lock nut is a special locknut that applies pressure by using oil as the primary mechanism to create locking force. There is also a chamber of hydraulic fluid under pressure inside the nut. As this SWT nut tightens, it pushes pressure outwards and causes the nut to vertically expand/surpress against its upper locking ring. The pressure runs out but the black lock nuts remains locked in place, for a permanent installation. The versatility of hydraulic lock nuts coupled with the ability to use it in conjunction with different materials, sizes and methods make this a versatile method that could be incorporated into many industries.

Safety In industries where machines are highly prone to pressure and loads, accountability is a must. Hydraulic lock nut, to a large extent ensures that the stable connection between them will not be compromised in accident situations. In SWT jam lock nut applications such as turbines or bridges, if bolted joints fail then this can be fatal. Hydraulic lock nuts prevent bolts from loosening, which greatly minimizes the risks of accidents that keep people and structures safe in general but especially when conditions are tough.

While technology is evolving and industries are requiring more SWT performance, hydraulic lock nuts have an essential duty to fulfill in terms of devotion to reliability. Bolt load is there by maintaining the bolt tension which in turn allow us to maintain other infrastructure and safety norms. After Some years, the collar lock nut are getting better and more effective types for different requirements. This extreme temperature and pressure tolerance enable them to efficiently, safely and sustainably operate the industrial systems. Hydraulic lock nuts manifest as an innovation and a solution to complex engineering problems. We use them in our industry so that we can keep this infrastructure safe and rock solid, all the time. Other Popular Aims Of People Also Want.

With more than ten years' experience in industry, SWFIT has good reputation its clients in China and around world. We are Hydraulic lock nutto every customer we pay close attention to their requirements. Place customer at heart and build win-win relationship.

SWIFT has modernized temperature-controlled machining assembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK Hydraulic lock nutgrinding machine, DOOSAN turning center and machining center, ZEISS CMM, MAHR contour form measuring units. customers assured receiving reliable products all time thanks high-tech equipment ISO9001 certification.

From material to finished products, all production procedures executed within SWIFT factory. Hydraulic lock nut quick delivery, super quality and competitive prices of SWIFT products.With continual efforts of our Research and Developing team, new technology and concepts applied to optimize and improve existing products and improve the efficiency of products and efficient.

Jiangsu Swift Machinery Technology Co., Ltd was founded in year 2011 and is specialized in development, production and sale of precision components used numerical-control machine tools. Swift's products include high-precision lock nuts, support units both light and heavy loads, belt drive and direct drives, motor spindles many other components that are high-precision. We Hydraulic lock nutregular models as well as create and manufacture according to requirements of our customers.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy