Presenting the SWT-SWT/RN Series tall Precision Lock Nut from the product which is reliable, SWT. This lock nut is specifically created and engineered to provide accuracy that is high precision in commercial applications.

Created using top-quality materials and manufacturing that is advanced, this lock nut guarantees durability, stability, and consistency. It's perfect for used in precision instruments such as device tools, laser gear, and hands being robotic. The SWT-SWT/RN Series tall Precision Lock Nut is actually a item that will fit the bill whether you are within the manufacturing industry or simply just require a safe fasten for your gear.

Among the many key top options that come with this product is its power to supply a tight and grip that is secure. The nut's high precision threading ensures a company connection between your bolt and also the nut, preventing loosening and vibration that is reducing. This ability helps it is an option this is certainly perfect used in environments being confronted with constant movement or vibrations that are harsh.

Another advantage of this lock nut is its ease of installation. The nut may be firmly guaranteed to your bolt, and it's also ready to utilize with only a couple of simple actions. The nut's lightweight and design this is certainly lightweight allows you to help keep and transport.

The SWT-SWT/RN Series Precision that is tall Lock could be corrosion-resistant and will withstand extreme conditions, rendering it ideal for found in both interior and surroundings being outside. Its resistance to wear and tear ensures that it shall stay in exemplary condition even with extensive usage.

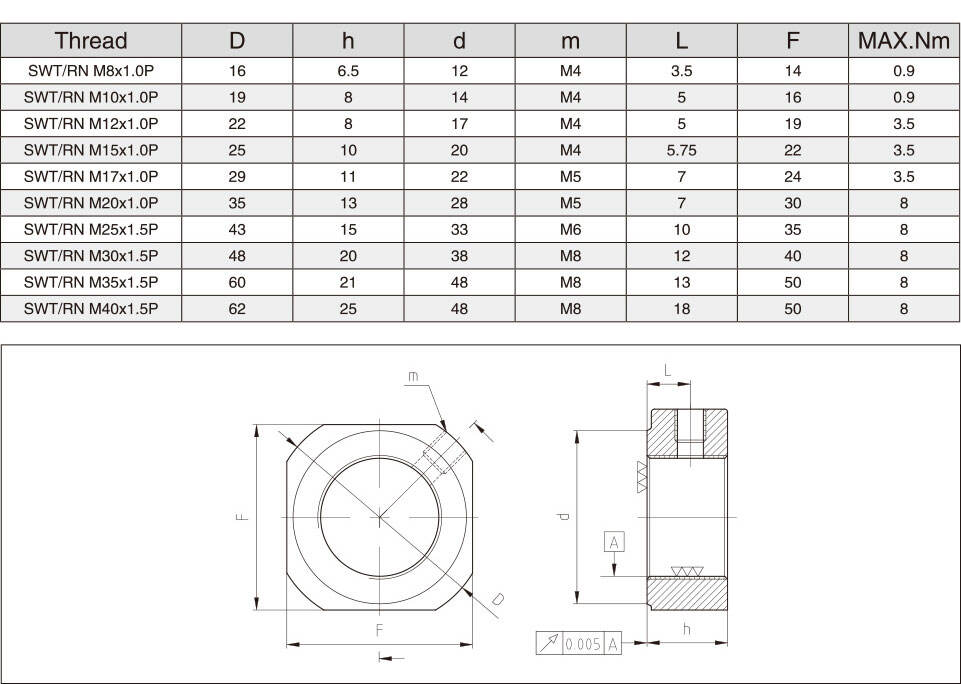

The SWT/RN lock nuts are square and could easily and precisely fixate the ball srew and bearings. Nut thread and surface are machined at the same time, which ensures the high precision.

Material:#45 steel

Hardness: HRC28-32

Thread precision:ISO4H

Run out: 0.005mm

Jiangsu Swift Machinery Technology Co., Ltd, established in 2011, specializes in precision components for numerical control machine tools. The company boasts accreditation, having passed TS16949 and ISO9001-2008 certifications. It's also listed on the National Equities Exchange and Quotations (commonly known as New Third Board) since December 2016.

SWIFT operates modernized, temperature-controlled machining and assembly workshops. The facility houses top-tier equipment, including the SWISS STUDER universal grinding machine, Japanese OKAMOTO Surface Grinder, Korean DOOSAN turning center and machining center, and German ZEISS CMM, and MAHR contour and form measuring units. All production processes, from materials to finished products, occur within SWIFT's factory, ensuring swift delivery, superior quality, and competitive pricing.

Additionally, the Research and Development team consistently endeavors to enhance existing products with updated technology and innovative ideas, aiming to optimize productivity and efficiency.

Product Series:

Machine Tool Spindles: BT30/40/50, HSK-A63, HSK-A100 Belt-drive, Direct-drive, Motor Spindle, Spindle for Lathe, etc.

Precision Lock Nuts: M8~M200 (8 series: R/F/K/A/FA/AN/RN/N) Grade: JIS1

Support Units: SWT WBK17~WBK40 (DF, DFF, DFF), EF/EK/AF/AK/FF/FK/BF/BK

Powder Metallurgy Products: 27 series (applicable to various guideways)

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy