Role of CNC spindle Performance in Quality Machining

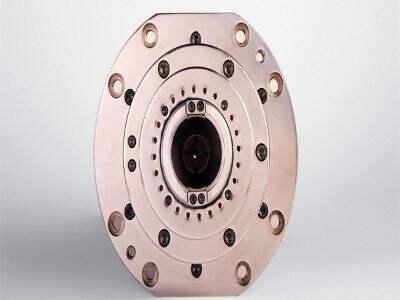

Within the machining world, the performance of a CNC Spindle is very important as it has a direct impact on the quality of your end product. However what is a CNC Spindle we must respect, and also why does it matter so much.

The Factors Affect CNC Spindle Performance, Impacting Machining Quality

There are various factors play a significant role in the performance of machining through cnc motor spindle Spindle Shape and Quality Short Lifespan Comparatively High Costs Lower performance. An important factor is the revolution number of a spindle. If the spindle spins faster, it will be more precise and these cuts can be smoother.

Optimizing CNC Spindle Performance for Maximum Machining Quality

CNC mill spindle is very important to achieve best and smooth machining quality. Regular spindle maintenance and calibration to maximise efficiency.

The relationship between CNC spindle speed and machining quality

The quality of the machining process greatly depends upon the speed and accuracy of a cnc spindle. Cuts can be rough and inconsistent if you spindle speed is too low not good for a finish! On the other hand if the speed is set very high, it can harm your material making an inferior product.

Conclusion

The CNC Spindle Performance is the key parameter to achieve the perfect machining quality. To provide high-quality parts, it is essential to know spindle performance parameter and act very smart to optimize it for yielding superior final products.