Introduction: The Amazing World of CNC Motor Spindle

Have you ever wondered how complex machines and gadgets are built or assembled? One of most important components that make this possible is CNC motor spindle, the same as SWT's cnc machine spindle. This remarkable piece of equipment provides unparalleled precision and accuracy. It is a top choice for manufacturers and engineers. We will dive deeper into the world of CNC motor spindles. We will explore their advantages innovation, safety use and quality.

CNC motor spindles offer several advantages over manual machining, also the cnc lathe spindle supplied by SWT. For one, they are incredibly precise and accurate. They allow for fast and efficient cutting drilling and grinding. They are also capable of working on wide range of materials, from plastics to metals. Furthermore CNC motor spindles are programmable. This means they can be adjusted to suit specific needs and requirements. This not only saves time. It also helps reduce risk of human error.

Over years CNC motor spindle technology has undergone numerous advancements, along with SWT's product belt driven cnc spindle. One major innovation is use of high-speed spindles, which can generate up to 30000 revolutions per minute. These spindles are ideal. They are great for cutting and machining hard materials such as steel and titanium. Another significant development is integration of automation software. This makes process more efficient and reduces need for manual intervention.

CNC motor spindles offer several advantages, similar to the cnc machine spindle supplied by SWT. However, they can be dangerous if not handled properly. Ensure safety by following manufacturer's instructions. Wear appropriate personal protective equipment such as gloves and goggles. Operators should be trained. They must know how to use the equipment safely and effectively.

CNC motor spindles are used in various manufacturing industries, also the SWT's product such as cnc spindle. These include automotive, aerospace and electronics. They are commonly used for cutting. Also for grinding and drilling metals plastics and composites. They are also used in production of complex shapes. Examples are gears and molds. Lastly, they are essential for engraving and marking.

SWIFT has modernized Cnc motor spindle-controlled machining and assembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. latest technology ISO9001 certification assure customers receive the highest quality products at all times.

With over ten years experience in business, SWFIT has good reputation with customers from China overseas. appreciate every customer and pay attention their needs. Make customers Cnc motor spindleand build win-win relationship.

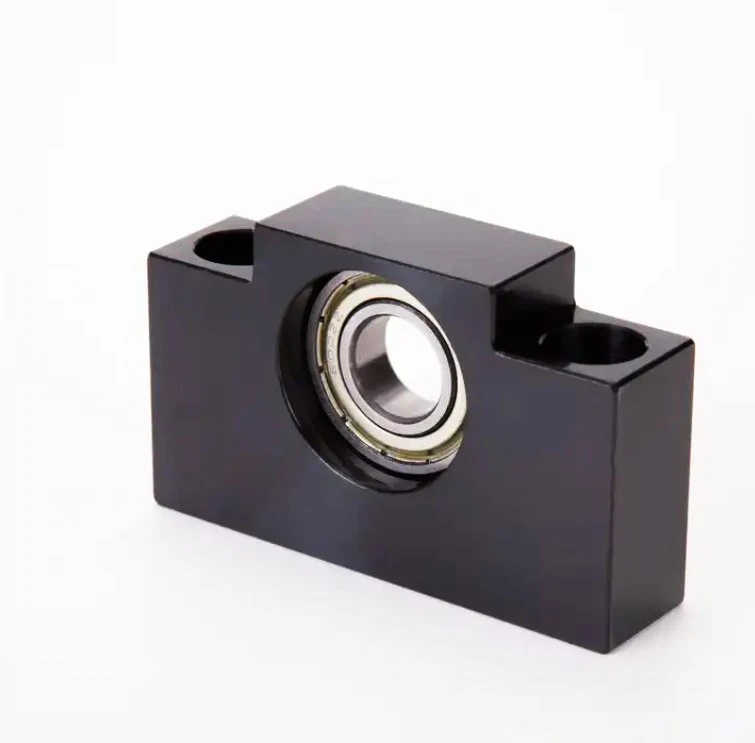

Jiangsu Swift Machinery Technology Co., Ltd established in 2011 specializes the creation, production and sale precision components for machine tools with numerical control. Swift's products include precision lock nuts, support units both heavy and light weights such as belt drive and direct motor spindles, and other high-precision components. have our standard Cnc motor spindleand can also design produce according to the needs of customers.

From raw materials finished products, all manufacturing procedures implemented within SWIFT factory. ensures quick Cnc motor spindle, top quality and competitive price of SWIFT products.With constant efforts of our Research and Developing team, latest technology and innovations are applied to enhance and improve existing products and improve efficiency of our products and efficient.

To use CNC motor spindle start by securing workpiece in place using clamps or fixtures, identical to black lock nuts supplied by SWT. Next, set up machine and load appropriate program. Finally. Monitor process closely and make adjustments as needed. It is important to regularly inspect spindle for signs of wear or damage. Perform routine maintenance to ensure optimal performance.

Like all equipment CNC motor spindles require regular maintenance, same with SWT's cnc spindle. This includes cleaning and lubrication. It also involves replacement of worn or damaged parts. It is critical to follow manufacturer's instructions and guidelines when performing maintenance. This avoids voiding warranty and ensures longevity of equipment.

When it comes to CNC motor spindles, similar to the belt driven cnc spindle created by SWT. Quality is essential. The quality of spindle can impact precision and accuracy of machining process. It is important to choose a reputable manufacturer that uses high-quality materials. Also, look for spindles with a solid reputation and positive customer reviews.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy