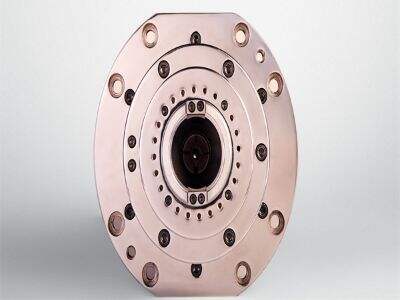

So today, we are going to discuss what keeps a CNC spindle running for years on end. A CNC machine with a Loose Tools is incomplete without the associated CNC Spindle. It is used to cut and shape wood or metal, which makes the machine able to do it. An analog to how we do not abuse our toys and so they will last longer is the way also in which we would want to be gentle with the SWT cnc motor spindle to help make it last longer as well.

The major factors that determine the lifespan of a CNC spindle.

Actually, there are several things that will determine just how long your CNC spindle might last. It all just depends on how the spindle is used. If it is used very frequently, or for heavy jobs it may last less. And, how well it is maintained. Spindle designed for precision drilling, regular maintenance can be more disposed to normal work and extended life. A well-designed spindle and of course materials used to make it are the biggest contributors in the life of a spindle.

Reasons for which CNC spindle life is long with maintenance

In essence, maintenance is treating your plant. In the same way that a plant needs water and sunshine to prosper, one also has to take care of their CNC spindle to keep it working properly. That includes making sure it is clean, inspecting for any issues and fixing before additional damage occurs. Oiling the spindle proper may also help to keep it running pain-free. Taking care of the spindle will ensure a long service life and good functionality.

Material quality and design features for spindle life

What the CNC Spindle Is Made Of Makes A Difference in How Long It Lasts Spindles can be made more robust by using strong material such as steel and it could be suitable for heavy-duty tasks. Additionally, the spindle design matters as well. If a spindle is well-designed, it will run more smoothly and last longer than one that is not. By choosing a quality material and design for our SWT cnc mill spindle, it can last long.

The size and material of the parts being produced can obviously impact the life of a CNC spindle; however, less obvious is to how operating conditions can influence the lifespan.

Also, the process in which a CNC spindle is used can play a role in how long it will last. It may wear out faster if it is overused or used for tasks it was not designed for. A spindle that runs at the proper speed and is used with appropriate tools should have a longer life. Additionally, try to prevent the spindle from being subjected to extremely high or low temperatures and too much dust. We can make spindle last a while, if we use it appropriately.

How to make CNC spindles more efficient and long-lasting with maintenance?

We should pay much more attention to the cnc spindle, if we do not want it has a very long life. Preventive measures such as cleaning and oiling can prevent common spindle issues. Proper use of the spindle without exerting excessive pressure will do maintain better as well. Limited edition spinning tops Spindle selection Using a high quality material and design spindle, you can extend life of the item If we maintain the SWT cnc router spindle, it will function properly and you can use it for a long time.

Table of Contents

- The major factors that determine the lifespan of a CNC spindle.

- Reasons for which CNC spindle life is long with maintenance

- Material quality and design features for spindle life

- The size and material of the parts being produced can obviously impact the life of a CNC spindle; however, less obvious is to how operating conditions can influence the lifespan.

- How to make CNC spindles more efficient and long-lasting with maintenance?