Machines have different components and one common component amongst them are machine spindles. They ensure that machines operate effectively and perform their tasks accurately. Machine cnc spindle — from A to Z: Breakdown and Explained We'll discuss what they do, how to choose the right one, how you should take care of one, and then we'll cover some new technology that will make them even better and more efficient

We like to think of machine spindles as the heart of a machine. As our hearts allow us to spin and live, the spindles allow machines to spin and move. Spindles are present in very diverse types of machines. They’re in drills that create holes; lathes that carve material; in milling machines that slice things into certain shapes. Spindles are what makes the machines do their work properly because without them machines would not function properly.

In industrial and factory settings, machine spindles are critically important. They guide machines how to cut, drill and source of materials to a very precise amount. When the machines have good cnc motor spindle, they can do the necessary work without failures. So even if the machine is nice, if the spindle is not good, the machine might not work well, convenience and work might be problem. That is why choosing the right spindle for every machine is imperative. We can efficiently interface between the machine and the spindle to provide smooth operation and accurately measured results.

When selecting a machine electric spindle for your project, there are several key factors to consider. You need to determine its spindle size first. The spindle must fit to your machine and this is very important. When it is not the right size, too big or too small, it will cease to function correctly! Next, you need to consider how fast and powerful the spindle needs to be. Every job needs a certain performance at speed. And, of course, a spindle that runs at a very high speed is required for certain tasks, while others require a slower spindle that is more powerful. You need a spindle suited to the work you are performing, so everything operates evenly.

Maintaining machine spindles in good working condition, and increasing their lifespan requires proper maintenance. That means allowing them to be regularly clean and lubricated so that they can continue to work smoothly without jamming. Also, inspection for scratches, damaged parts and replacing it immediately if you notice any issues. There can be many reasons if a spindle does not work properly, such as dirt or lack of oil. So it should be able to figure out what exactly is wrong and resolve the situation as fast as possible — to keep the machinery running smoothly.

There is never ending evolution in technology and machine spindle technology is no different. Spindles are now more precise and efficient than ever due to new designs and advancements. AT A GLANCE Modern spindles have sensors that detect problems before they occur. If it is a spindle error the spindle can tell you so you can fix it before it becomes a real issue. Other spindles are designed better and are stronger and more durable, so they are performed extremely heavy work as they do not break down.

With over ten years experience in the industry, SWFIT has good Machine spindlesits clients in China as well as overseas. cherish every customer attach great importance to the needs of each customer. Customers at the heart of our company. We work hard create an environment that is win-win everyone.

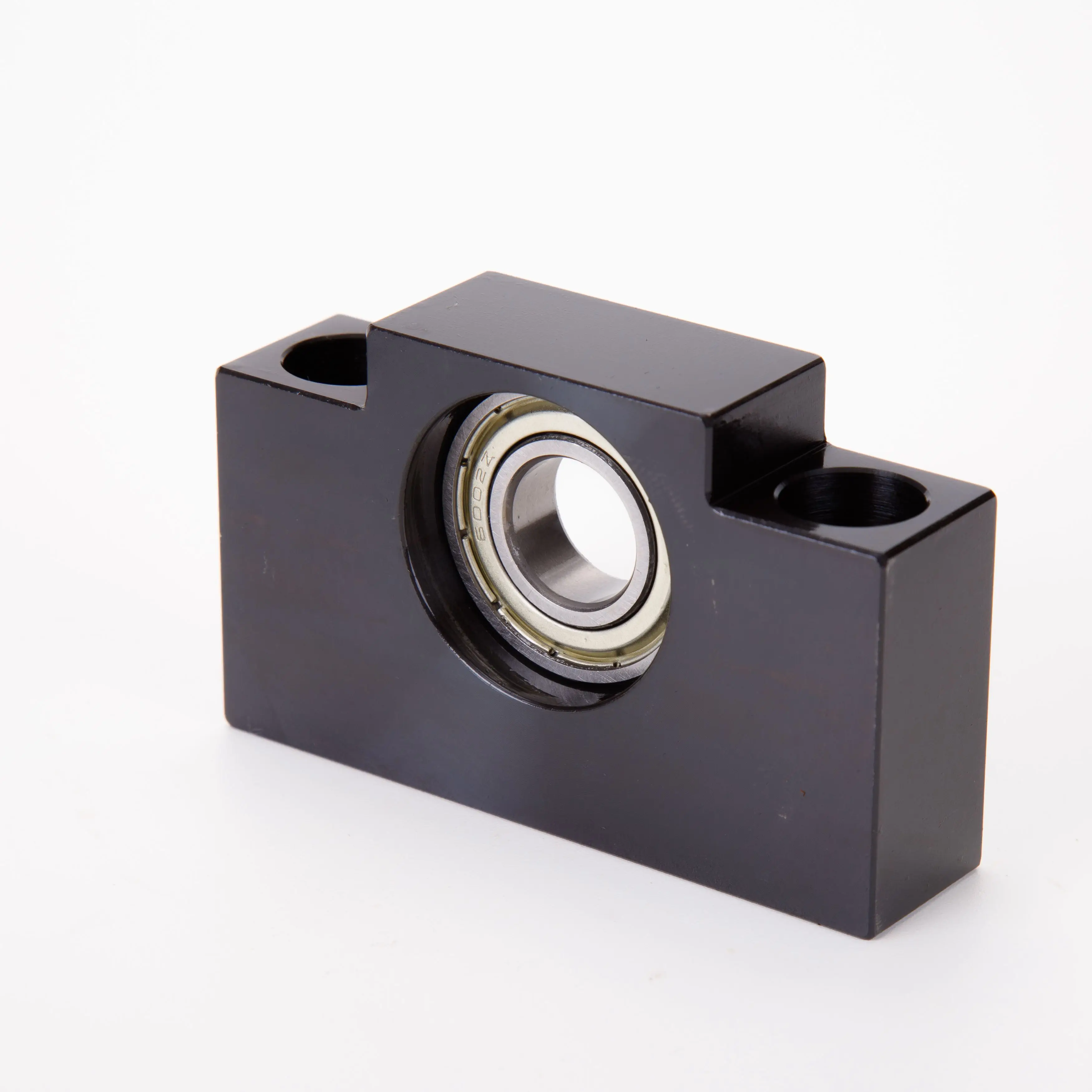

Established 2011, Jiangsu Swift Machinery Machine spindlesCo., Ltd a leader in designing, producing and selling components that precision for numerical control machine tools. Swift's products include precision locks, nut, support unit both heavy light weight, belt drive, direct drive lathe spindles motors as well as other high-precision components. We offer standard models, but we can also make and design products according to customers' requirements.

SWIFT has modernized temperature-controlled Machine spindlesassembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. advanced devices ISO9001 certification assure that our clients will receive reliable products all times.

Research Development team continuously strives Machine spindlesand enhance products, making them more efficient productive.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy