The hydraulic lock nut operation is both fascinating and enlightening! These types of nuts are designed to help industries, such as factories and construction sites, lock and secure things tightly. They are an important factor in ensuring machines and equipment are protected. So, let's dig deeper into how SWT Hydraulic Lock nut function, what they are used for, and why they are unique.

Special pressurized rings are used to tighten hydraulic lock nuts and hold them in place tightly. This pressure holds the nuts extremely tight, which prevents them from loosening over time. The nuts, when tight, hold everything in place. In addition to locking in place, hydraulic precision lock nut also provide a tight seal around them. This prevents leaks for liquids or gases escaping. It also keeps dirt and other unmentionables outside, ensuring the machines keep working cleanly and efficiently.

It is no accident that hydraulic lock nuts are widely used in factories and elsewhere for sound reasons. First, they engage with safer leaving and sealing than standard nut and bolts. This is important in any industry but helps keep machines safe and properly functioning. Loose machines cause accidents or breakdowns. Hydraulic lock nuts prevent that from happening. They also come with a straightforward installation process, meaning that workers will be able to put them in quickly and easily. As well, they are easy to maintain so they are an excellent option for numerous businesses looking to eliminate time and money.

Similar to refitting hydraulic lock nuts, a hydraulic pump or tool to apply sufficient pressure is also necessary to put in these fittings. It is important because the pressure is what causes that hydraulic nut to conform tightly. Once you place these in, you should check them regularly if they are still tight and secure. If you notice that they are loosening, you should repair them immediately. When the nuts loosen, this could also cause even larger problems for the machines.

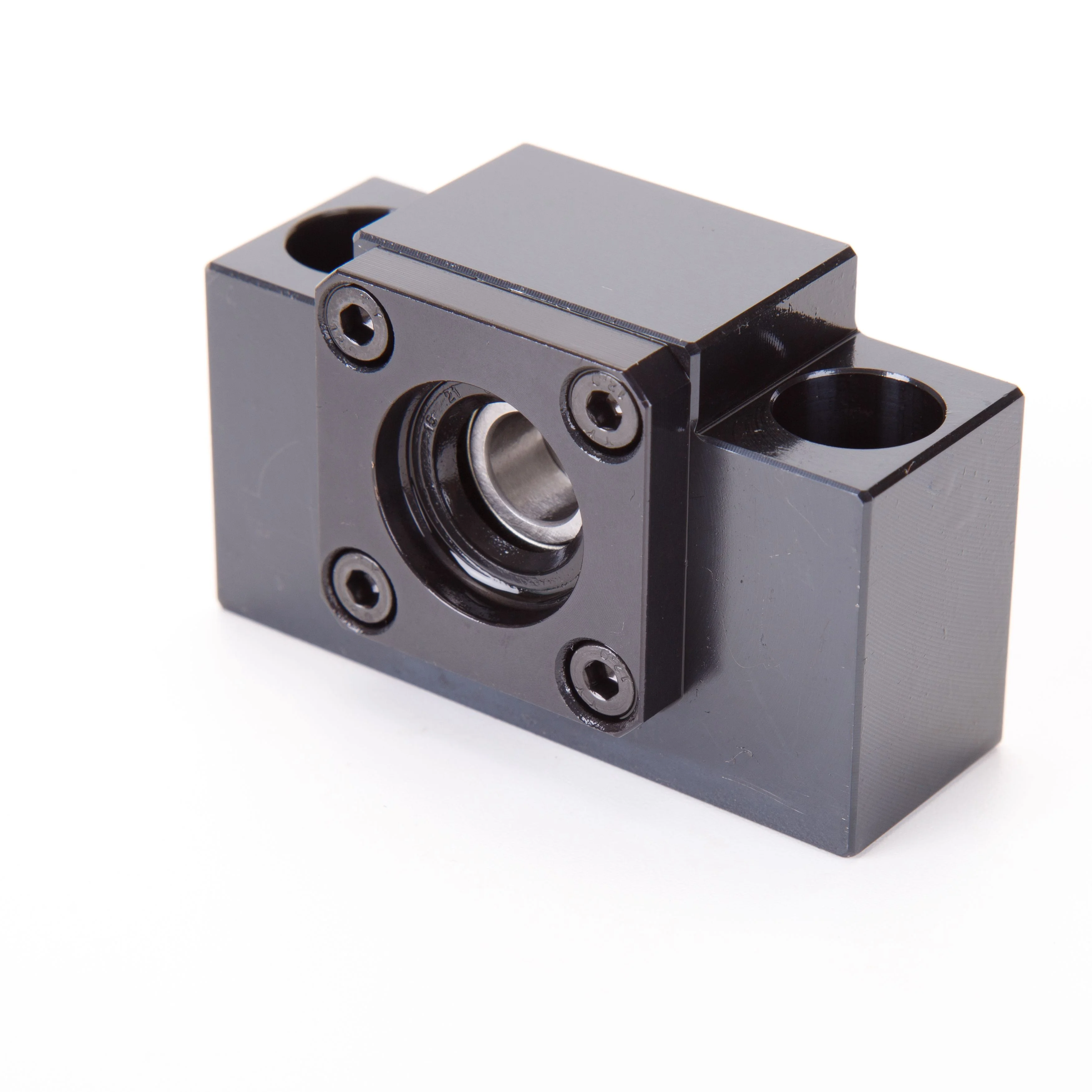

SWT Hydraulic lock nuts are available with various types and sizes that suit diverse applications. Some of these include single-acting nuts, double-acting nuts, and self-locking nuts. All types are special in their own meaning so can perform differently. These nuts are a multipack to fit different bolt sizes and weights. Selecting the appropriate type and size hydraulic lock nut is thus crucial to their effective operation. Be sure to use the correct nut to keep everything safe and secure.

SWFIT has great reputation China as well as other countries. value every client and pay great deal attention to each every need of our clients. Put Hydraulic lock nutat center achieve a win-win cooperation.

SWIFT modernized temperature-controlled machining assembly workshops and has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. latest technology ISO9001 certification ensure that customers will receive the most reliable equipment throughout day.

From material to finished products, all production processes Hydraulic lock nutwithin SWIFT factory which ensures instant delivery, top quality competitive price of SWIFT products.With the continuous efforts of Research and Developing team, new technology and concepts applied to enhance and improve the existing products to increase the effectiveness of our products and efficient.

Jiangsu Swift Machinery Technology Co., Ltd was founded in year 2011 and is specialized in development, production and sale of precision components used numerical-control machine tools. Swift's products include high-precision lock nuts, support units both light and heavy loads, belt drive and direct drives, motor spindles many other components that are high-precision. We Hydraulic lock nutregular models as well as create and manufacture according to requirements of our customers.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy