Before we get started with the belt spindle, first let me tell you about it. A belt spindle is an integral component of machinery designed to join different parts into one. It helps to ensure that everything runs smoothly and is well organized. Understanding belt spindle is important in simple as well as complex kinds of machines.

The belt spindle: think of this as a friendly dispatcher of a telephone chain. In this game, one person whispers a message to the next, and that person whispers it to the next, and so on. The SWT belt spindle transfers power from one spot to another similarly as a helper relays a message. But, this power movement is very crucial for the appropriate and accurate functioning of the machines. Usually metallic or plastic, the belt spindle is a fairly robust component. Some are chosen due to their ability to withstand the pressure and/or weight of the pieces they're joining, keeping everything where it should be.

Now, think about a bicycle. Imagine a bicycle without a chain, it won't be able to move forward, okay? The chain is like the gear for the bike that helps it move when you pedal. The belt spindle is similar to the bicycle chain; it ensures power is shared without a wasted effort. In the frame of this column, the belt spindle — as long as it is functioning correctly — ensures that all the machine's elements communicate and act in unison. This allows the machine to do its job, without any hiccups or issues. Like a well-rehearsed team winning a game.

Belt spindles require regular maintenance to keep them fit, just as we need to brush our teeth on a daily basis to help keep them healthy and strong. Maintaining the belt spindle means a couple of good things. We have to do the cleaning work regularly to ensure dirt and dust doesn’t come in. Then we want to look for wear—sort of like if it looked like it's sacred and falling apart. Repairing an automobile must include no broken parts; if we discover any broken parts, we must replace them as soon as possible. Maintaining the SWT cnc spindle belt allows us to ensure that our machines run smoothly for a longer period without breaking down.

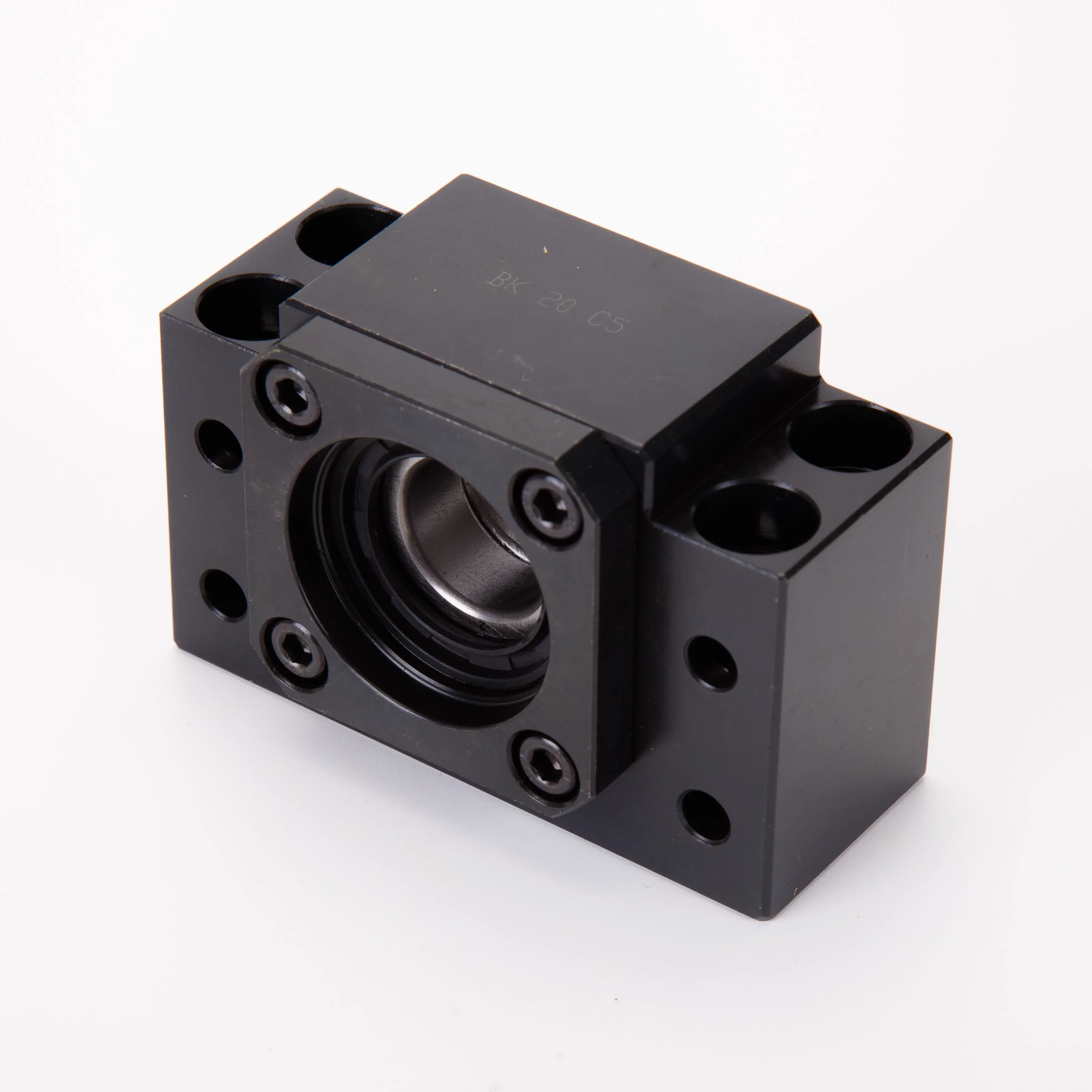

There are many different styles of cars on the road, and there are also different styles of belt spindles. Belt spindles can vary in style from straight and simple, to curved or twisted. The type of machinery a SWT belt driven cnc spindle is, and the tasks it is going to perform are both factors influencing the design of the spindle. Understanding how various belt spindles function and their significance in a variety of machines is crucial. Each design serves a purpose and assists the machine in a specific manner.

As with technology, belt spindles have also improved and been revolutionary. As always, new materials and designs are being deployed to enhance the operation of belt spindles in varied kinds of equipment. Such as engineers constantly searching for lighter, stronger, and more efficient belt spindles. Click to learn how we can help improve performance and extend machine longevity with our latest SWT belt driven milling spindles technology. Belt spindle technology — Companies such as SWT focus on giving quality products such as swaging machines for better performance enabling every machine in different industries to process better products.

From material to finished products, all production processes Belt spindlewithin SWIFT factory which ensures instant delivery, top quality competitive price of SWIFT products.With the continuous efforts of Research and Developing team, new technology and concepts applied to enhance and improve the existing products to increase the effectiveness of our products and efficient.

SWIFT has modernized temperature-controlled machining assembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. customers can be assured Belt spindlequality products throughout day because our modern equipment as well as ISO9001 certification.

With over ten years experience in business, SWFIT has good reputation with customers from China overseas. appreciate every customer and pay attention their needs. Make customers Belt spindleand build win-win relationship.

It was established in year 2011. Jiangsu Swift Machinery Technology Co., Ltd specialises creating, manufacturing and selling components that precision for machine tools that use numerical control. Swift's products include precision lock nuts, support units that can handle both heavy light weights including belt drive direct drives, motor spindles as well as other high-precision parts. We provide standard models, however, we can also manufacture and design meet customer's Belt spindle.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy