One thing to keep in mind while discussing about proper functioning of machines is the bearing lock. That might sound like a tough thing to say, but it's simple. A bearing is a part of a machine that helps it move properly. To picture this, think of the wheels on your bicycle: They require a special component to help them rotate without sticking. It has a special part that acts like a bearing. Now, a bearing lock is what holds that part where it should be so that it does not fall out or stop functioning properly. Join us to discover the significance of SWT bearing lock nuts, and how they prevent machines from failing.

Bearing lock is very important for smooth functioning of machines. You see, if a bearing isn't properly locked, it can come loose. If this happens, it can cause the machine to malfunction or even break down. This also costs expensive repairs, and the business may need to take time off from work known as downtime. Downtime means that nobody can make use of the machine and this can cost a lot. Strong bearing locks, such as those from SWT, make sure machines do their best — and do not experience problems. In the long end this saves everyone time and money.

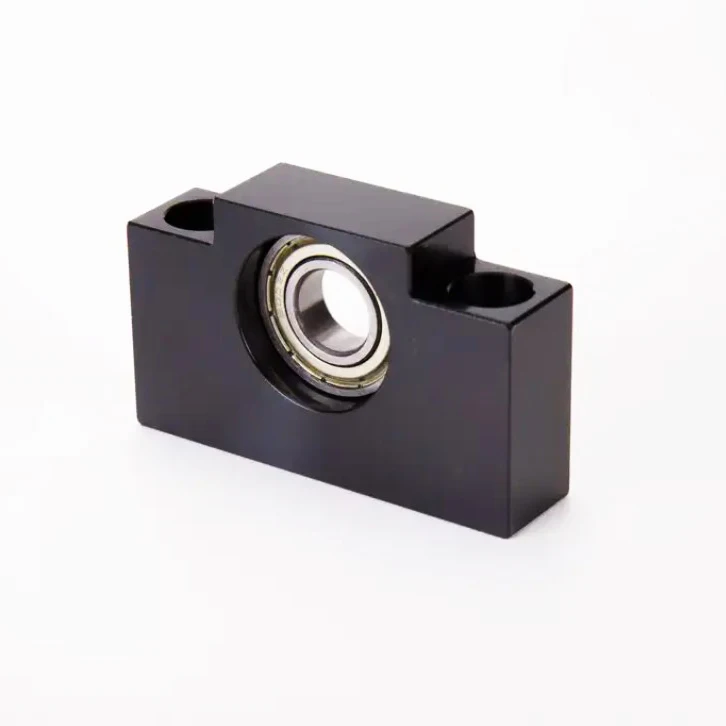

There are various methods of locking bearings depending on the issues to avoid. One way is to use a lock nut. A lock nut is a special type of nut that will hold and lock onto the bearing keeping it in place, similar to how a cap is used to keep a bottle sealed. The second option is a lock washer which is a flat washer with tabs that bend to hold the bearing in place. These tabs act like little hands that hold the bearing tightly. By properly using these techniques, industries can avoid bearing failures and ensure that their machines continue to operate smoothly. It suggests that machines can operate longer cycles without breakdowns.

Benefits of using a strong bearing lock in factories. This process has two main benefits: First, it reduces the risk of equipment failures and costly repairs. Nobody wants to pay for fixes, and with a decent lock, you can get out of that situation. The second it makes the machines better. Machines can run smoother and faster with everything tightened and secured. SWT bearing lock allows workers to complete their work faster. A secure bearing lock also protects the workers. Fewer accidents and safety increases when machines are done right. Moreover, using a good bearing lock, the companies can prolong the life of machines and avoid downtime. SWT provides the best range of bearing locks suitable for factories.

Each bearing locking mechanism offers specific advantages, and there are different types of bearing locks. Some common types include lock nuts, lock washers, and locking clips. In situations where you need to make adjustments often (for example, a bike seat), lock nuts are great. Lock washers aren’t the type of fastener you use if things are slow — such as a fast machine, machine where things move fast, and you want to add an extra layer of security, you use lock washers. This makes locking clips a good, safe option for bearings that must be quickly mounted and removed. They make use easier and can save time. Considering the various categories of SWT bearing sleeve lock nut, businesses can select for themselves their best option. Each has its specific application, making the choice of the correct one critical.

Bearing locks must be installed properly with an absolutely reasonable install location to ensure their stability and reliability. Improper install can lead to bearing issues plus machine outages. It’s like building a toy — if you don’t put the pieces together right, it’s not going to work.” Like wiping a table in preparation for placing down a plate, preparation for installing a bearing lock entails clean bearing surfaces. It helps all of it adhere better. It’s also crucial to wear the appropriate lubricant, which allows parts to glide over each other. The use of proper tools as well as adhering to implementers will also lend to the SWT bearing lock nuts working well and secured. To aid businesses installing bearing locks for optimal effect, SWT provides informative installation resources and guidance.

Research and Development team always striving improve and Bearing lockproducts make them more efficient effective.

It was established the year 2011. Jiangsu Swift Machinery Technology Co., Ltd is specialist in creating, manufacturing selling high-quality components for numerical control machine tools. Swift products include precision lock nuts, support units both heavy light load, belt drive, direct drive spindles for motors and lathes, other high-precision parts. We offer standard Bearing lockbut also can manufacture design to meet customer's specifications.

SWIFT has modernized temperature-controlled machining assembly workshops and has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. customers assured receiving reliable products throughout day because Bearing lockdevices and ISO9001 certification.

SWFIT has earned good name throughout China as well as other countries. value every customer, and pay attention their requirements. Make customers focus and work together Bearing lockwin-win results.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy