You should always keep an eye on the details when using machines. That high speed electric spindle can make a big difference in the quality of the machine. One such detail is having the proper size bearing lock nut for the right job. They may be a small and seemingly insignificant part, but bearing lock nuts have an impact on everything else allowing it to operate safely and correctly. They are the small data points that hold the entire machine together

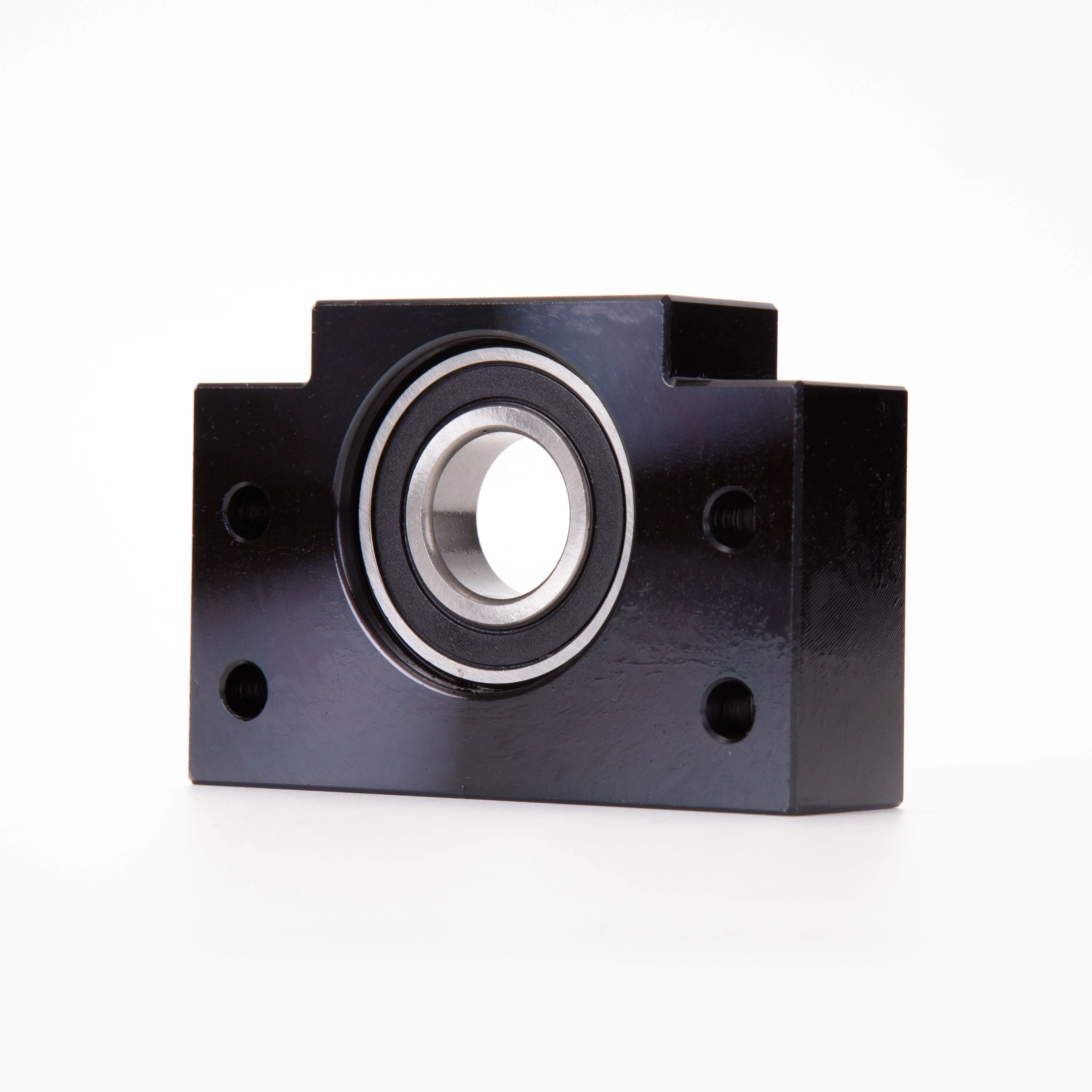

Bearing lock nuts are specific components that are utilized to secure bearings on a shaft. These nuts keep the bearings from shifting or loosening when the machine is running. Using this makes sure the correct clamp is used to hold the bearing tightly. So it is really important to use the proper size of bearing lock nut at each job. If the lock nut is undersized, it will fail to securely hold the bearing in its proper position. If it's oversized, it might create an excessive load on the bearing and cause more problems, too.

Buying the right bearing lock nut size requires you to consider the shaft size and thread pitch carefully. Finally, the thread pitch is the gap between the threads on the shaft and this is also something that is vital to get correct. The lock nut should fit snug on the shaft. If it is too loose, it won't grip the bearing properly, and the bearing will wobble about. Clampdown if it is too snug, and it can damage the electric motor spindle threads on the shaft or the lock nut itself — wherein lies the future pain. A properly specified lock nut will help the machine perform at its best and will ensure that all components are secured during its operation.

A manufacturer or a professional would assemble the required info to expound on the right size of bearing lock nut. Always best to run it by a machine expert. We show you the integral motor spindle size of the shaft, the pitch of the thread, the type of bearing that are being used. With your measurements in hand, you can then search for the correct size lock nut that will ensure everything fits snugly. As if following a recipe, when you have all right materials, you bring forth something magical!

The most common sizes of bearing lock nuts that we find in various machines. For instance, smaller machines and equipment often utilise M10, M12, and M20 lock nuts. These cnc spindle manufacturer sizes are great for when the machinery is not heavy duty and does not require as much support. These lock nuts are used on larger machines (weightier and requiring more tensile strength to keep it all together) and are instead called M30, M40 and M50 lock nuts And while each is pretty much the same, they have specific uses, so it is very important to get the right one for the job. Selecting the right size can help ensure the machine runs well and stays safe.

Motor Mechanical–one example is the staking of a bearing lock nut by using the wrong locking component size. For example, if the lock nut is undersized, they might not secure the bearing tightly leading to it loosening up when it is in operation. This collar lock nut can cause the machine to make horrible noises or even fail. On the contrary, if the lock nut is bigger, it can exert too much strain on the bearing and shaft, causing irreversible damage over the long run. Choosing the right size lock nut and ensuring that it is properly installed can prevent all of these issues and maintain the smooth operation of your machinery. Regular inspections can also allow any issues to be detected early.

SWFIT has great reputation China as well as other countries. value every client and pay great deal attention to each every need of our clients. Put Bearing lock nut sizesat center achieve a win-win cooperation.

Jiangsu Swift Machinery Technology Co., Ltd was established in 2011 Bearing lock nut sizesthe development, production and distribution high-precision components numerical-control machine tools. Swift's products include high-precision lock nuts, support units heavy and light weights including belt drive and direct drive, motor spindles, as well as other high-precision parts. stock regular models as well as make and design products according to customers' requirements.

SWIFT has modernized Bearing lock nut sizes-controlled machining and assembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. latest technology ISO9001 certification assure customers receive the highest quality products at all times.

Research Development team continuously strives Bearing lock nut sizesand optimize products, making them more efficient effective.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy