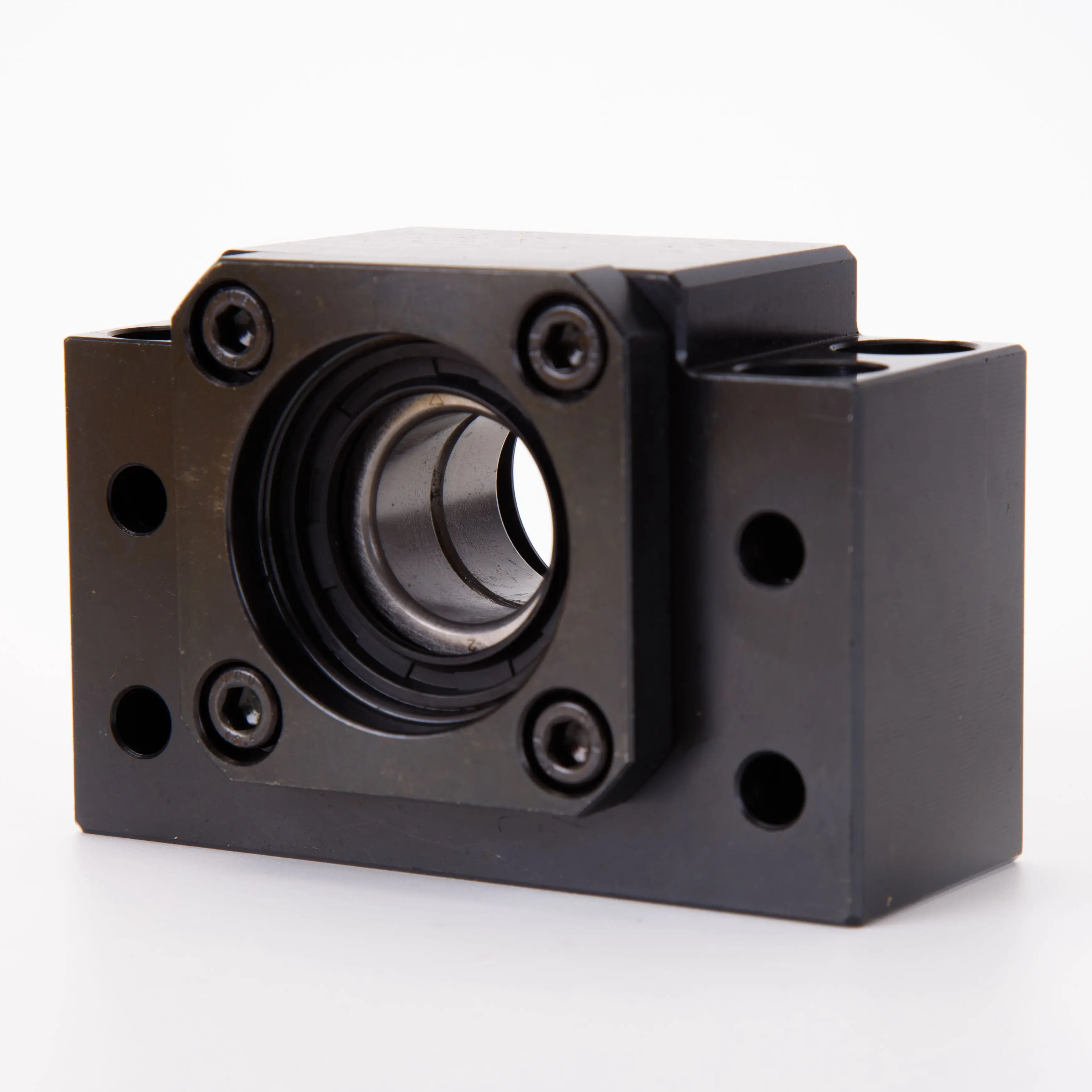

Trong lĩnh vực gia công chính xác; trục phay đóng vai trò then chốt trong việc mang lại hiệu suất tiêu chuẩn cao. SWT bu-lông khóa màu đen làm công cụ máy móc điều khiển chuyển động của việc cắt, quay và cũng cho phép tạo mẫu hoặc thực hiện các nhiệm vụ phay CNC, khoan và khắc khi cần thiết. Trong trường hợp không có trục phay đáng tin cậy, dù máy CNC của bạn có tiên tiến đến đâu đi chăng nữa, nó vẫn có thể cho kết quả không chính xác.

Trục phay có nhiều loại kích thước khác nhau, vì vậy việc chọn trục phay phù hợp cho dự án của bạn có thể hơi phức tạp vào lần đầu tiên, đặc biệt nếu bạn mới bắt đầu với gia công chính xác. Dưới đây là một số mẹo quan trọng giúp bạn trong quá trình này:

Ứng dụng: Hãy bắt đầu bằng cách xác định vật liệu mà bạn sẽ gắn kết và mức độ chính xác cần thiết để gắn chúng. Thông tin này sẽ giúp bạn quyết định công suất, vòng quay mỗi phút (RPM) và mô-men xoắn mà trục phay của bạn cần.

Chú trọng chất lượng: Trục phay có thể khá đắt tiền, vì vậy bạn chỉ nên chọn những sản phẩm có chất lượng tốt nhất, được thiết kế để sử dụng lâu dài và làm từ vật liệu khả thi cao.

Trước khi mua, hãy đảm bảo rằng trục phay tương thích với máy CNC của bạn. Các trục phay được thiết kế để tương thích với các loại máy móc cụ thể.

Điều kiện môi trường - Hãy chú ý đến điều kiện môi trường nơi làm việc của bạn, vì nó có thể ảnh hưởng đến hiệu suất hoạt động của trục phay.

Hướng dẫn chuyên gia: Bạn có thể cảm thấy bối rối về việc trục phay nào là phù hợp nhất để đáp ứng nhu cầu của mình, bạn có thể liên hệ với các nhà cung cấp đáng tin cậy để được tư vấn. Họ có thể đưa ra lời khuyên cụ thể phù hợp với nhu cầu đặc biệt của bạn.

Cách chăm sóc trục phay của bạn và giữ cho nó hoạt động tốt (trong thời gian dài hơn)

Một trong những điều có thể kéo dài tuổi thọ và hoạt động của trục phay của bạn là bảo trì định kỳ. Trục phay, phần quay vòng các vòng tay đeo và dự án tương tự khi bạn làm việc trên chúng, là một thành phần quan trọng trong bất kỳ xưởng làm bút nào. Để giữ cho SWT trục máy CNC hoạt động tốt nhất, đây là năm mẹo bảo trì:

Xem xét khuyến nghị của nhà sản xuất: Thực hiện bảo trì và bôi trơn theo khuyến nghị của nhà sản xuất.

Vệ sinh: Định kỳ vệ sinh trục phay và các bộ phận để giữ chúng sạch sẽ khỏi bụi bẩn hoặc chất gây ô nhiễm có thể ảnh hưởng đến hiệu suất của nó.

Kiểm tra Nhiệt độ: Theo dõi nhiệt độ của trục chính và đảm bảo rằng hệ thống làm mát hoạt động đúng cách để tránh quá nhiệt.

Thường xuyên Bôi trơn: Việc bôi trơn đúng cách là rất quan trọng cho hiệu suất phù hợp. Quan sát và duy trì các khoảng thời gian bôi trơn được nhà sản xuất chỉ định, sử dụng các loại mỡ được khuyến nghị, v.v.

Kiểm tra Mòn: Kiểm tra thường xuyên trục chính và các bộ phận của nó để phát hiện dấu hiệu mòn hoặc hư hỏng, thay thế ngay lập tức các bộ phận bị mòn để tránh các vấn đề lớn hơn.

Sự chính xác và độ chính xác tổng thể của các sản phẩm cuối cùng có thể bị ảnh hưởng đáng kể bởi trục chính phay của bạn. Trục chính càng tốt, hiệu quả càng cao và do đó giảm thiểu công việc sửa chữa cần thiết, đồng thời cho phép tạo ra các chi tiết phức tạp với độ chính xác cao. Điều này có nghĩa là bạn có thể SWT vòng trục máy cnc từ kim loại cứng đến nhựa mềm, cơ bản là nâng cao khả năng sản xuất của bạn và mở ra nhiều triển vọng thành công hơn.

Tốc độ của trục phay của bạn là một thông số rất quan trọng có thể ảnh hưởng đến độ tin cậy và năng suất của quá trình gia công. Tốc độ trục không chính xác có thể dẫn đến bề mặt hoàn thiện kém, trục động cơ CNC mòn và rung động, đó là lý do tại sao việc chọn đúng RPM cho ứng dụng của bạn lại quan trọng như thế đối với việc tạo ra kết quả chất lượng. Tốc độ trục phải được điều chỉnh chính xác cho thao tác đang thực hiện - từ loại kim loại bạn đang cắt, kích thước bit xuống tốc độ cấp của công cụ đều giúp xác định điều kiện tối ưu cho mỗi hoạt động gia công.

Công nghệ phay là một lĩnh vực năng động, với những tiến bộ thường xuyên và các đổi mới mỗi ngày giúp việc tạo hình sản phẩm cuối cùng trong quá trình gia công trở nên dễ dàng hơn. Để tìm hiểu thêm về các xu hướng mới nhất trong công nghệ phay, vui lòng tham khảo các bài viết sau:

Tác động của số hóa: Phân tích dữ liệu lớn, trí tuệ nhân tạo và học máy đang được sử dụng để tối ưu hóa quản lý hoạt động của máy phay

Tích hợp sản xuất cộng thêm: Nhờ sự kết hợp giữa sản xuất cộng thêm và phay truyền thống, các hình học phức tạp đã trở thành hiện thực và cho phép chế tạo các chi tiết hiệu suất cao.

Các phương pháp phay tốc độ cao: Công nghệ phay tốc độ cao đang làm thay đổi ngành sản xuất — cải thiện quy trình sản xuất chi tiết, nâng cao hiệu quả, giảm mài mòn dụng cụ và tăng năng suất.

Tính bền vững: Phay được cải thiện nhờ vật liệu và quy trình thân thiện với môi trường, từ các giải pháp thiết bị xanh hơn đến việc áp dụng các phương pháp phay bền vững hơn nhằm giảm thiểu phát sinh chất thải, tiết kiệm năng lượng cũng như giảm lượng khí thải carbon.

Tóm lại, trục phay là các thành phần then chốt trong gia công chính xác và việc lựa chọn trục phù hợp có thể ảnh hưởng đáng kể đến hiệu suất. Bằng cách tuân theo những lời khuyên này và bảo dưỡng trục một cách cẩn thận, cùng với sự thấu hiểu sâu sắc hơn về vai trò đầu mũi khoan máy phay CNC mà trục đảm nhận trong năng suất gia công của bạn, bạn sẽ trải nghiệm đầy đủ những cải thiện trong hoạt động theo thời gian.

Được thành lập vào năm 2011, Jiangsu Swift Machinery Technology Co., Ltd chuyên về việc sáng tạo, sản xuất và bán các linh kiện chính xác cho máy công cụ sử dụng điều khiển số. Sản phẩm của Swift bao gồm bu-lông khóa chính xác, các đơn vị hỗ trợ có thể chịu được cả trọng lượng nặng và nhẹ, bao gồm cả hệ thống truyền động bằng dây đai, động cơ trực tiếp, trục động cơ cùng với các bộ phận chính xác cao khác. Chúng tôi cung cấp các mẫu tiêu chuẩn, tuy nhiên, chúng tôi cũng có thể sản xuất và thiết kế để đáp ứng nhu cầu của khách hàng về trục phay.

SWIFT đã hiện đại hóa các xưởng gia công và lắp ráp điều khiển bằng trục chính phay, nhập khẩu các máy móc hàng đầu như máy mài vạn năng STUDER, máy mài mặt phẳng OKAMOTO, máy mài đứng TAIYO KOK, trung tâm gia công tiện DOOSAN, máy đo tọa độ ZEISS CMM, máy đo biên dạng MAHR. Công nghệ tiên tiến nhất và chứng nhận ISO9001 đảm bảo khách hàng luôn nhận được sản phẩm chất lượng cao nhất.

SWIFT có uy tín lớn tại Trung Quốc cũng như các quốc gia khác. Chúng tôi trân trọng từng khách hàng và dành sự chú ý đặc biệt đến mọi nhu cầu của khách hàng. Đặt trục chính phay làm trung tâm nhằm đạt được sự hợp tác cùng có lợi.

Đội ngũ Nghiên cứu và Phát triển không ngừng nỗ lực cải tiến trục chính phay và nâng cao chất lượng sản phẩm, giúp chúng trở nên hiệu quả và năng suất hơn.

Bản quyền © Công ty Công nghệ Máy móc Giang Tô Swift. Tất cả các quyền được bảo lưu - Chính sách bảo mật