CNC Spindle Belts: Just a really strong rubber band one could imagine inside all the machines of a big factory. These cool belts serve a very key function as they transfer power from the motor to the spindle. The spindle is the part of your machine that causes the cutting tool to rotate. This turning is what makes holes or shapes in metal or other materials we use to create things. Production would slow down without these belts, and the machines wouldn't run properly.

CNC Spindle Belts are used in machines that work at the same intensity as us, especially on days at school that are full of commitments. They work very hard (so need to be serviced often to keep doing their job well). Keep the Spindle Belt CNC In good condition A Spindle Belt CNC is usually subject to operational failure. Regular inspections and cleaning of the belt, ensuring it is in tight condition and not worn can prevent costly issues and repairs in the future. Taking care of these belts is further beneficial is this way we can save time and money which is extremely good for everyone in the factory.

Because CNC Spindle Belts require time and special attention. #1 — Check Belts for cracks or tears Run the rubber belt: After replacing the belt, it is very necessary to check the motor and spindle which runs the belt to ensure that they are also working properly. Schedule regular belt inspections to ensure everything stays running smoothly. This allows you to change them out before they become too worn out and snap. SWT is a well-known brand in the industry where good quality belts are required as they last longer, and provide the best performance.

Quality CNC Spindle Belts (https:spindelconcrete.com) are very essential for machines' reliable & efficient work. A good belt makes enough power flow from the motor to the spindle and makes the production process smooth and efficient. Using high-quality belts makes them last longer, reduces maintenance and repair costs, and saves money in the future. Good products we use help us to avoid problems that can lead to production failure.

In manufacturing, CNC Spindle Belts are crucial. Many machines depend on CNC Spindle Belts, such as lathes, which shape things, milling machines which cut and shape things, routers which carve patterns, and grinders which smooth surfaces. Belt types differ and differ in strength and speed that carry out on specific tasks. Its selection of belt type is entirely determined by the specific production tasks required by the factory. Belts also vary widely in width, thickness and color, so you can find the right one for virtually any machine.

SWIFT has modernized temperature-controlled machining assembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour measuring units. modern equipment ISO9001 cnc spindle beltassure that clients will receive most reliable equipment every time.

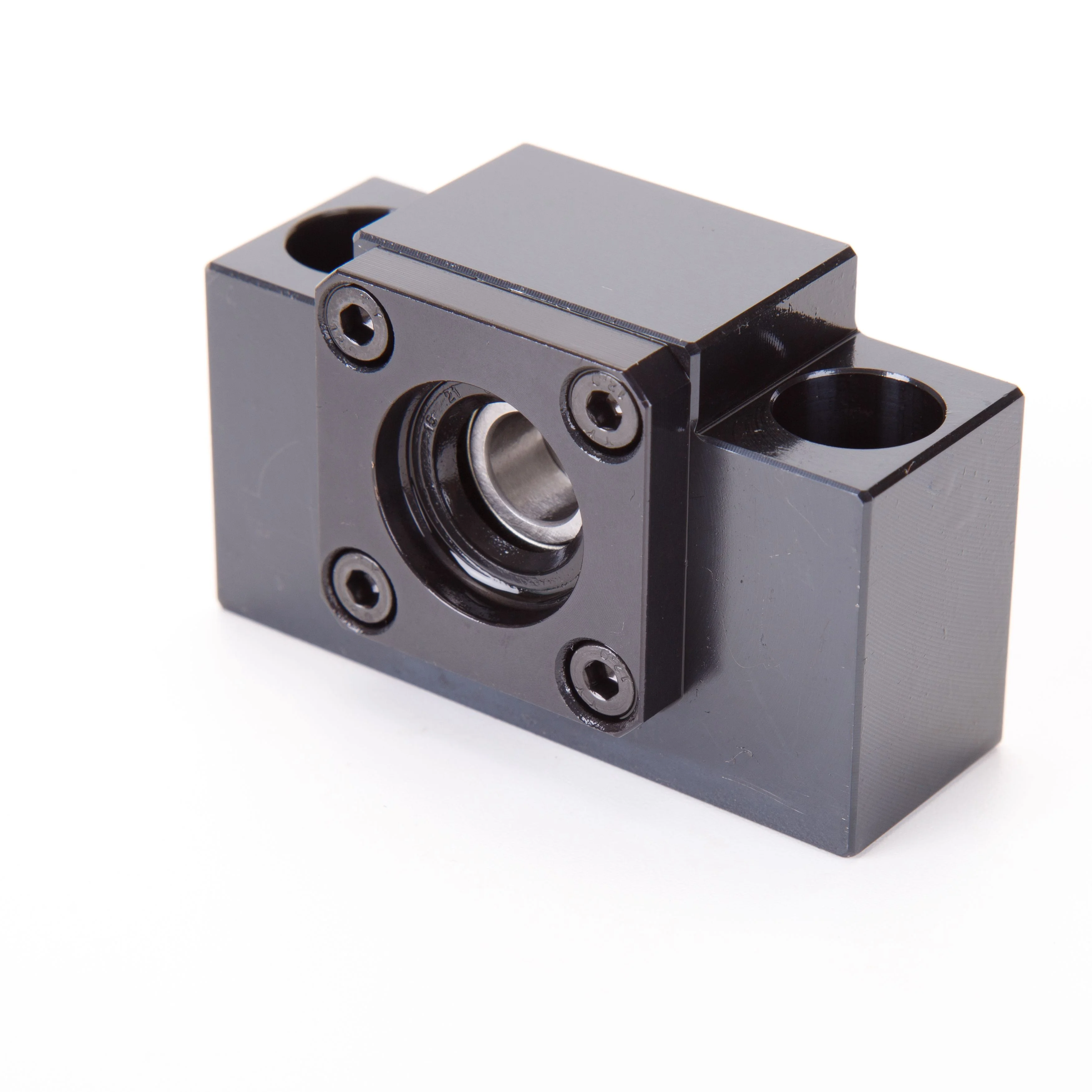

Jiangsu Swift Machinery Technology Co., Ltd established in 2011 specializes the creation, production and sale precision components for machine tools with numerical control. Swift's products include precision lock nuts, support units both heavy and light weights such as belt drive and direct motor spindles, and other high-precision components. have our standard cnc spindle beltand can also design produce according to the needs of customers.

Research Development team continuously strives cnc spindle beltand enhance products, making them more efficient productive.

With more than ten years' expertise field, SWFIT has good reputation among cnc spindle beltChina and across the globe. cherish every customer and pay a great deal of attention to needs of each customer. Make customers the focus work together to achieve win-win results.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy