Έχοντας είναι ένας από τους πρόδρομους στην παραγωγική επεξεργασία από τα χρόνια, τα μηχανήματα φρεατίου του SWT είναι απλώς διαμόρφωση υλικών με ακρίβεια που δεν είναι μικρότερη από τέχνη που έχει περιλαμβάνει. άξονας φρέζας cnc είναι ένας από τους πιο σημαντικούς συστατικούς που μπορούν να συγκριθούν με το καρδιάκο νύχι σε αυτό το μηχανικό θαύμα. Το εργαστήριο υλικό κρατάται με κάθετο ή οριζόντιο άξονα, η πιο πολύπλοκη μορφή περιστροφής ελέγχεται μέσω αυτών των μηχανισμών και επιτρέπει πολλές χρήσιμες γεωμετρίες. Σε αυτό το άρθρο, μαθαίνουμε λεπτομέρειες για τον αξόνα μιας μηχανής φρεατινού από τη σχετικότητά του και τα κριτήρια επιλογής μέχρι τις βελτιώσεις στην ανάπτυξή του, καθώς και μερικές συμβουλές συντήρησης, ακολουθούμενες από τον ρόλο που διαδραματίζει σήμερα στον τομέα της μηχανοποίησης.

Το SWT ηλεκτρικός αξόνας cnc δεν είναι απλώς ο άξονας περιστροφής, λειτουργεί επίσης ως μεταφορέας όσον αφορά τη δύναμη από τον τόρνο στο εργαστικό υλικό. Η σχεδιασμός, η αρθρωτότητα και οι δυνατότητες ταχύτητας ενός τόρνου καθορίζουν το είδος των εργασιών που η μηχανή μπορεί να εκτελέσει καθώς και πόση ακρίβεια θα επιτύχει. Ένας επιτυχημένος άξονας είναι εκείνος που τρεμούσε όσο το δυνατόν λιγότερο κατά τη λειτουργία του και βοηθάει να επιτευχθεί ένας ισχυρός τερματισμός με στενές ανοχές. Να γνωρίζετε τον άξονα, το εύρος φορτίου του, το φάσμα ταχύτητας και τη συμβατότητά του με διαφορετικά συστήματα εργαλείων είναι κεντρικής σημασίας.

Είναι σημαντικό να επιλέξετε τον σωστό άξονα για τη μηχανή τόρνο σας, μην τον κάνετε αυτόν τον επιλογή γρήγορα. Το πρώτο σημαντικό πράγμα που πρέπει να σκεφτείτε είναι η προορισμένη χρήση, θα είναι βαριά κοπή ή λεπτοί τερματισμοί; Ο τύπος του υλικού και η σκληρότητά του έχει μεγάλη επίδραση στην απαιτούμενη ροπή και ιπποδύναμη. Το σύστημα άξονα στο integral motor spindle πρέπει να είναι συμβατό με τις απαιτήσεις της λειτουργίας, είτε πρόκειται για κρούσταλλα για εφαρμογές υψηλών ταχυτήτων ή για κυλινδρικά κρούσταλλα για βαριές φορτίες. Επιπλέον, η ακρίβεια και η αποδοτική αλλαγή εργαλείων εξαρτάται από την δέσμευση της κορυφής της αxonοποιητή με τους κρατητές εργαλείων. Τελευταία αλλά όχι ελάχιστη, δώστε προσοχή στην ικανότητα της αxonοποιητή να διατηρεί σταθερή ταχύτητα υπό μια σειρά φορτίων, καθώς αυτό εγγυάται την παραγωγικότητα και την ποιότητα των κοματιών.

Η καινοτομία στην τεχνολογία SWT έχει αλλάξει τον τρόπο λειτουργίας των τραπεζιών. αξονοποιητής υψηλής ταχύτητας με ηλεκτρισμό με προηγμένα συστήματα ψύξης επιτρέπουν ταχύτερες περιστροφές χωρίς υπερθέρμανση, βελτιώνοντας την παραγωγικότητα και μειώνοντας τους χρόνους κύκλου. Οι οδηγούμενες με CNC (VFDs) κανονιστές καθιστούν εύκολη την ελέγχου της ταχύτητας και επιτρέπουν περίπλοκες μορφές. Επιπλέον, η χρήση κεραμικών και χάλκινων μερών σε υβριδικά συστήματα κρούσταλλων βοηθάει να μειωθεί η διατριβή και να επεκταθεί η ζωή της αxonοποιητή. Αυτά τα τεχνολογικά πρόοδα δεν μόνο αυξάνουν την αποτελεσματικότητα ενός μηχανήματος τραπέζιου, αλλά και την πολυτέλειά του.

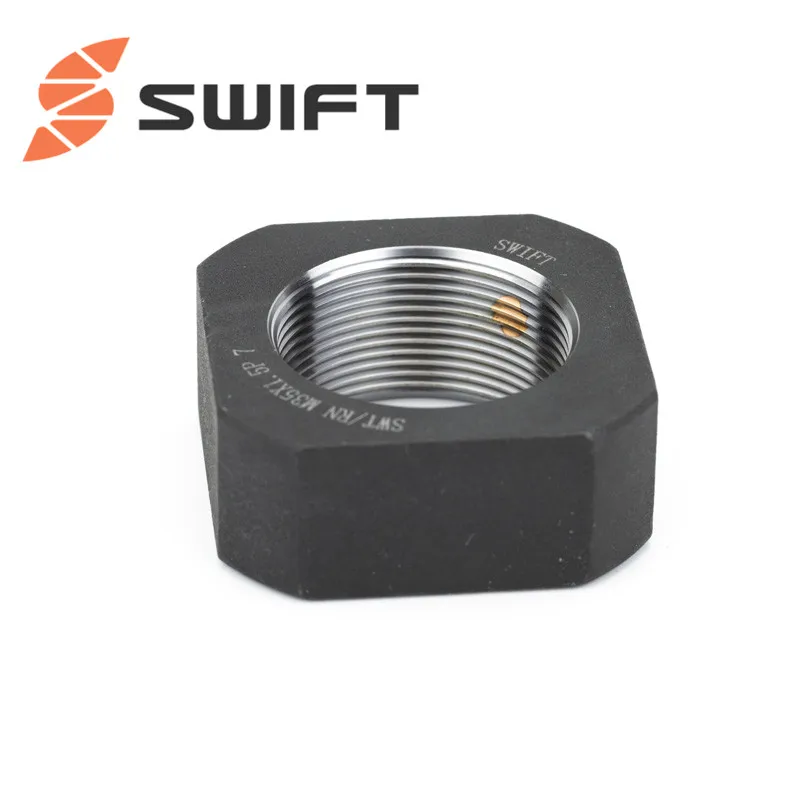

Για να εξασφαλίσετε την ζωή της αxonοποιητής του τραπεζιού σας, κλειδών μπράκιου με κολάρι είναι σημαντικό να φτιάχνεται αυτή η τύπος καρύδα από το SWT. Η λίψη με ποιοτικά υγρά ή λιποβάφες κρατάει τα βαλτσάκια να τρέχουν ομαλά και μειώνει την έξωση. Είναι σημαντικό να επιβλέπετε τη θερμοκρασία, γιατί πολύς ζεστασιάς μπορεί να ζημιώσει γρήγορα τα μέρη του αντρικού. Η κανονική καθαρισμός του αντρικού και τακτικά προλαμβάνει την καταστροφή από ξένα αντικείμενα. Είναι επίσης σημαντικό να ισορροπείτε το αντρίκι περιοδικά για να το κρατάτε κεντρικό και να μειώνετε τις τριλήψεις. Επιπλέον, η επένδυση σε ελέγχους στον σύνδεσμο του αντρικού μπορεί να προλάβει αποστολές που οδηγούν σε πρόωρη αποτυχία.

Η SWIFT εκσυγχρόνισε τα εργαστήρια συναρμολόγησης αξόνων τόρνων με έλεγχο θερμοκρασίας και έχει εισαγάγει πρωτοπόρα μηχανήματα γρανιτσαρίσματος STUDER, γρανιτσαρίσματος επιφανειών OKAMOTO, κατακόρυφου γρανιτσαρίσματος TAIYO KOK, κέντρου τόρνευσης και κέντρου κατεργασίας DOOSAN, συστήματος μέτρησης συντεταγμένων ZEISS CMM και μονάδων μέτρησης περιγράμματος και μορφής MAHR. Τα προηγμένα αυτά μηχανήματα και η πιστοποίηση ISO9001 διασφαλίζουν ότι οι πελάτες μας θα λαμβάνουν αξιόπιστα προϊόντα σε κάθε περίπτωση.

Ιδρύθηκε το 2011, η Jiangsu Swift Machinery Technology Co., Ltd ειδικεύεται στην ανάπτυξη, παραγωγή και εμπορία υψηλής ποιότητας εξαρτημάτων μηχανών εργαλείων που χρησιμοποιούν άξονες τόρνων. Τα προϊόντα της Swift περιλαμβάνουν ακριβείς ροδέλες ασφάλισης, μονάδες στήριξης για ελαφριά και βαριά φορτία, κινήσεις με ιμάντα, άμεσες κινήσεις, κινητήρες και άξονες τόρνων, καθώς και άλλα υψηλής ακρίβειας εξαρτήματα. Προσφέρουμε τυποποιημένα μοντέλα, ωστόσο μπορούμε επίσης να κατασκευάσουμε και να σχεδιάσουμε προϊόντα σύμφωνα με τις απαιτήσεις των πελατών.

Με πάνω από δέκα χρόνια εμπειρίας στον τομέα, το SWIFT έχει καλή φήμη για τα λαθών του παντρόπων στους πελάτες του στην Κίνα και σε διεθνές επίπεδο. Σεβόμαστε κάθε πελάτη και δίνουμε μεγάλη σημασία στις ανάγκες κάθε πελάτη. Οι πελάτες είναι στην καρδιά της εταιρείας μας. Δουλεύουμε σκληρά για να δημιουργήσουμε ένα περιβάλλον που είναι κερδιστικό για όλους.

Από τις πρώτες ύλες μέχρι τα τελικά προϊόντα, όλες οι διαδικασίες κατασκευής πραγματοποιούνται εντός του εργοστασίου SWIFT, γεγονός που διασφαλίζει άμεση παράδοση, εξαιρετική ποιότητα και ανταγωνιστικές τιμές για τα προϊόντα SWIFT. Με τις συνεχείς προσπάθειες της ομάδας Έρευνας και Ανάπτυξης, καινοτόμες ιδέες και τεχνολογίες εφαρμόζονται για τη βελτιστοποίηση και τη βελτίωση των προϊόντων άξονα τόρνων, καθώς και για την αύξηση της αποδοτικότητας των προϊόντων μας.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd Πάντα Πάντων Δικαιώματα Ρυθμισμένα - Πολιτική απορρήτου