Gear spindles are the most crucial components of machines. They guide machines to be able to move and function correctly. Gear spindles are not an uncommon machine. And without the wheels spinning, it’s really hard to ride a bike right? It wouldn’t go anywhere! That’s akin to what occurs when belt driven cnc spindles malfunction.

You can imagine gear spindles as muscles of a machine. Just like our muscles move our body, gear spindles turn and dock in to move different parts of the machine. For instance, in a bike, when you pedal, the gear spindles turn the wheels. That allows you to ride your bike peacefully down the street. Our gear spindles help them engage and disengage from each other like gears to make the machine run.

Tips on How to Maintain Your Gear SpindlesTaking good care of belt driven milling spindless is very important. To keep us healthy, we eat nutritious food and exercise; the same method should be said to gear spindles, they also want it for correct operation. If we fail to maintain those parts, they can break or cause the machine to stop functioning.” Think of it this way—what if a bike’s gear spindles, the peculiar technical bit there, snapped?

Proper maintenance of gear spindles is absolutely essential for ensuring the smooth functioning and high efficiency of machines. Machines in manufacturing plants and elsewhere rely on gear spindles to operate seamlessly. Machines can break down when gear spindles are not on point, leading to delays and major issues for all. That can cause a lot of frustration and even money lose, as the machines are not running.

Gear spindle also helps for even operation of machines. Efficiency is how well and quickly a machine does its job. If the gear spindles are old or not working well, the machine will not be able to work as fast or as well as it was designed to. This has the potential to stall work and cost time and money. Like when you want to run a race, but your shoelaces are tied together. You just will not be able to run as fast, and it will take you longer to complete the race.”

Different types of gear spindles are manufactured for different machines and jobs. Gear spindles can be powerful and robust for heavy-duty work, as in construction machinery, or small and delicate for precision work, as in watches. This tells us there is futuristic gear spindle for every work, much obliging and fortuitous.

assisting machines to work better, being very good to manufacture gear spindles Custom gear spindles may streamline the operation of a machine and increase design momentum. Machine reliability provides assurances to people that they will perform well, and not just stop working all at once.

Research Development team continuously strives gear spindleand optimize products, making them more efficient effective.

SWIFT has modernized temperature-controlled machining assembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK gear spindlegrinding machine, DOOSAN turning center and machining center, ZEISS CMM, MAHR contour form measuring units. customers assured receiving reliable products all time thanks high-tech equipment ISO9001 certification.

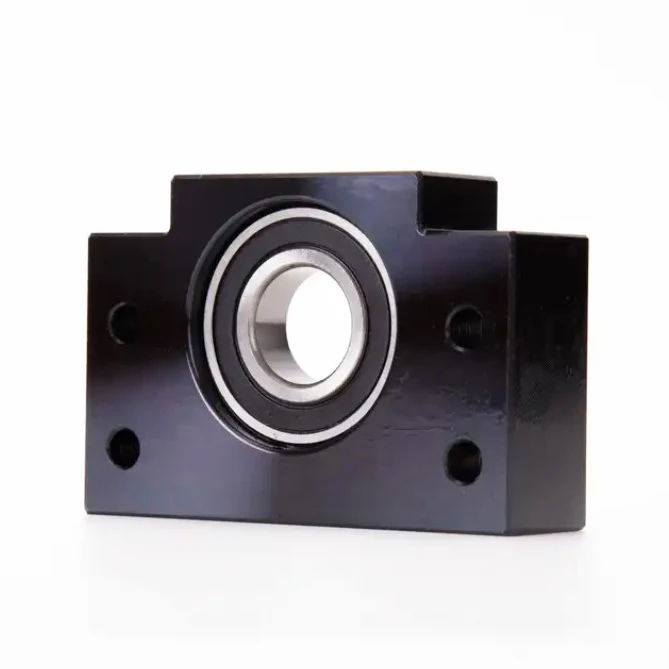

Established 2011, Jiangsu Swift Machinery Technology Co., Ltd specializes in development, production and selling high-quality components machine tools that use gear spindlecontrol. Swift's products include precision lock nut, support unit that both heavy light weight, belt drive, direct drive, motor and lathe spindles and other high precision components. offer standard models however, we can also manufacture design according customer's requirements.

With over ten years experience in business, SWFIT has good reputation with customers from China overseas. appreciate every customer and pay attention their needs. Make customers gear spindleand build win-win relationship.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy