Πρέπει πάντα να παρακολουθείτε τις λεπτομέρειες όταν χρησιμοποιείτε μηχανές. Που αξονοποιητής υψηλής ταχύτητας με ηλεκτρισμό μπορεί να κάνει μεγάλη διαφορά στην ποιότητα της μηχανής. Ένα τέτοιο λεπτό είναι να έχεις το σωστό μέγεθος φυλλωτήρα επισφραγίδων για το σωστό καθήκον. Μπορεί να είναι μικρά και φανερά ασήμαντα κομμάτια, αλλά οι φυλλωτές επισφραγίδες έχουν επίδραση σε όλα τα άλλα, επιτρέποντας την ασφαλή και σωστή λειτουργία της. Είναι τα μικρά σημεία που κρατούν την ολόκληρη μηχανή μαζί.

Οι φυλλωτές επισφραγίδες είναι συγκεκριμένα στοιχεία που χρησιμοποιούνται για να σταθεροποιηθούν οι επισφραγίδες σε έναν άξονα. Αυτές οι βρόχοι κρατούν τις επισφραγίδες από την μετακίνηση ή την ξεσκευασία κατά τη λειτουργία της μηχανής. Η χρήση τους εξασφαλίζει ότι χρησιμοποιείται η σωστή κλειδώση για να κρατάει την επισφραγίδα στενά. Έτσι είναι πολύ σημαντικό να χρησιμοποιείτε το σωστό μέγεθος φυλλωτής επισφραγίδος σε κάθε καθήκον. Αν η φυλλωτή είναι μικρότερη, θα αποτύχει να κρατήσει την επισφραγίδα στη σωστή θέση. Αν είναι μεγαλύτερη, μπορεί να δημιουργήσει υπερβολικό φορτίο στην επισφραγίδα και να προκαλέσει περισσότερα προβλήματα, επίσης.

Η αγορά του σωστού μεγέθους κλειδωμένου ημιάξοντα φορτίου απαιτεί να λάβετε υπόψη το μέγεθος του αξόνα και την πυκνότητα των νήματων. Τελικά, η πυκνότητα των νήματων είναι ο χάσος μεταξύ των νήματων στον αξόνα και αυτό είναι κάτι που είναι κρίσιμο να είναι σωστό. Ο κλειδωμένος δρομέας θα πρέπει να φιτώνει καλά στον αξόνα. Αν είναι πολύ ξεχασμένος, δεν θα κρατάει σωστά τον ημιάξοντα, και ο ημιάξοντας θα κινείται ασταθώς. Αν είναι πολύ σφιχτός, μπορεί να βλάψει τα electric motor spindle νήματα του αξόνα ή τον ίδιο τον κλειδωμένο δρομέα — εκεί ακριβώς βρίσκεται η μελλοντική πόνος. Ένας σωστά καθορισμένος κλειδωμένος δρομέας θα βοηθήσει το μηχάνημα να λειτουργεί με το καλύτερο τρόπο και θα εξασφαλίσει ότι όλα τα συστατικά θα είναι καταστημένα κατά τη διάρκεια της λειτουργίας του.

Ένας κατασκευαστής ή επαγγελματίας θα συγκεντρώσει τις απαιτούμενες πληροφορίες για να εξηγήσει το σωστό μέγεθος κλειδωμένου ημιάξοντα φορτίου. Πάντα καλύτερα να το διαβεβαιώσετε από έναν ειδικό των μηχανημάτων. Σας το δείχνουμε integral motor spindle μέγεθος του αξόνα, η πίστωση του νήματος, το είδος της κατασκευής που χρησιμοποιείται. Με τις μετρήσεις σου στο χέρι, μπορείς στη συνέχεια να αναζητήσεις το σωστό μέγεθος κλειδαριού φτερώματος που θα εξασφαλίσει ότι τα πάντα θα συνδεθούν σωστά. Σαν να ακολουθείς μια συνταγή, όταν έχεις όλα τα σωστά υλικά, δημιουργείς κάτι μαγικό!

Τα πιο κοινά μεγέθη κλειδαριών φτερώματος που βρίσκουμε σε διάφορες μηχανές. Για παράδειγμα, μικρότερες μηχανές και εξοπλισμοί χρησιμοποιούν συχνά κλειδάρια φτερώματος M10, M12 και M20. Αυτά κατασκευαστής αξόνων CNC τα μεγέθη είναι καλά για όταν η μηχανή δεν είναι βαριά και δεν απαιτεί τόση υποστήριξη. Αυτά τα κλειδάρια φτερώματος χρησιμοποιούνται σε μεγαλύτερες μηχανές (βαρύτερες και που απαιτούν περισσότερη συντριπτική ισχύ για να μείνουν όλα μαζί) και ονομάζονται M30, M40 και M50 κλειδάρια φτερώματος. Και ενώ κάθε ένα είναι πολύ παρόμοιο, έχουν συγκεκριμένες χρήσεις, έτσι είναι πολύ σημαντικό να επιλέξεις το σωστό για την εργασία. Η επιλογή του σωστού μεγέθους μπορεί να βοηθήσει να εξασφαλιστεί ότι η μηχανή λειτουργεί καλά και παραμένει ασφαλής.

Μηχανικό Μοτέρ–ένα παράδειγμα είναι η στήλωση ενός κουτσού φορτίου τροχαλιών χρησιμοποιώντας λαθός μέγεθος κλειδαριού συστατικού. Για παράδειγμα, αν ο κουτσούς είναι υποδιάστατος, δεν μπορεί να κρατήσει τις τροχαλιές στενά, πράγμα που μπορεί να οδηγήσει στην αποσυριδαγωγή κατά τη λειτουργία του. Αυτό κλειδών μπράκιου με κολάρι μπορεί να προκαλέσει στη μηχανή να κάνει δεινά ήχα ή ακόμη και να αποτύχει. Στο αντίθετο περιπτώσει, αν ο κουτσούς είναι μεγαλύτερος, μπορεί να βάλει πολύ μεγάλη πίεση στις τροχαλιές και τον άξονα, προκαλώντας αναστρέψιμες ζημιές με την πάροδο του χρόνου. Η επιλογή του σωστού μεγέθους κουτσού και η εγγύηση ότι εγκαταστάθηκε σωστά μπορεί να προλάβει όλα αυτά τα προβλήματα και να διατηρήσει την ομαλή λειτουργία της μηχανής σας. Κανονικές εξετάσεις μπορούν επίσης να εντοπίσουν οποιαδήποτε προβλήματα νωρίτερα.

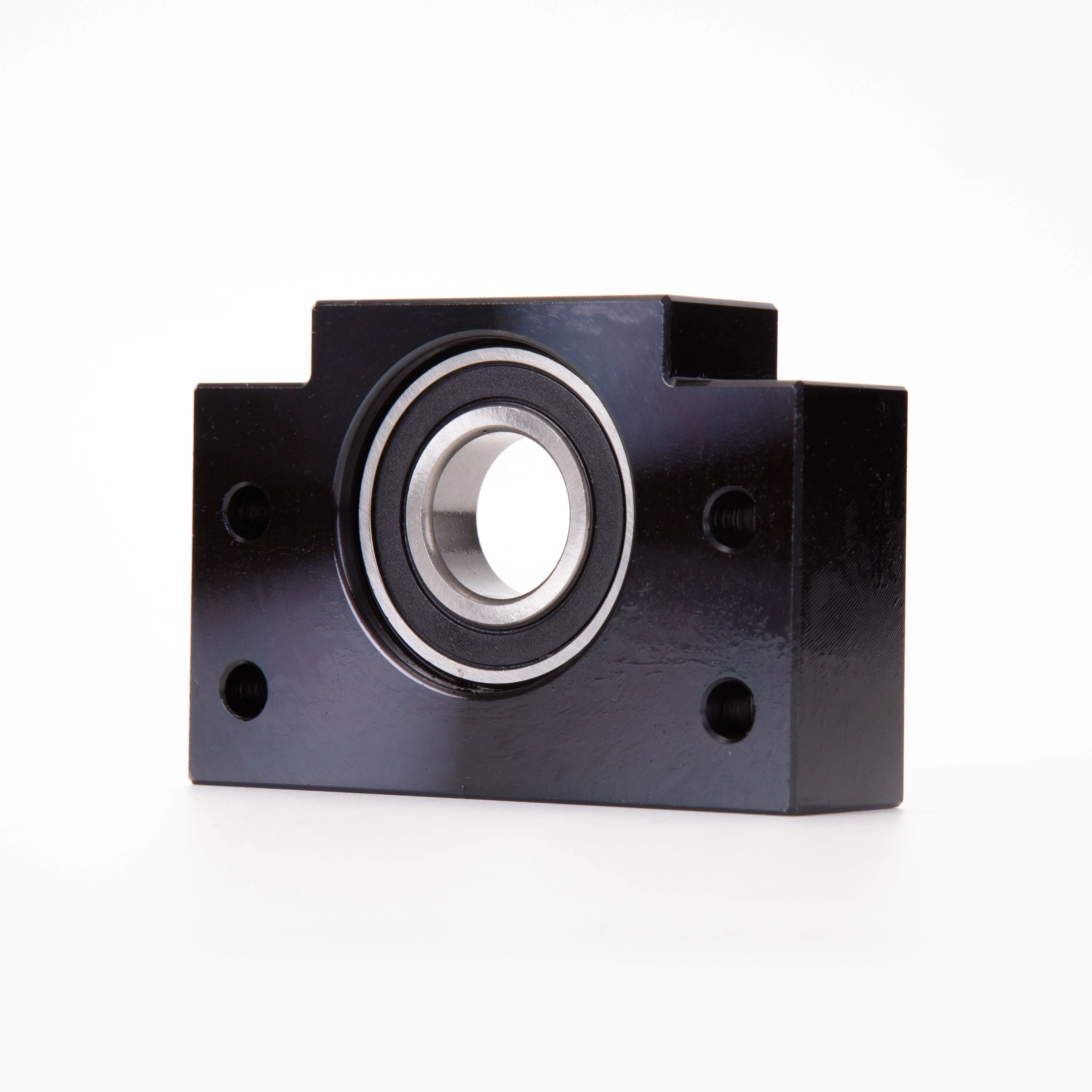

Η SWFIT έχει εξαιρετική φήμη στην Κίνα, καθώς και σε άλλες χώρες. Εκτιμούμε κάθε πελάτη και δίνουμε ιδιαίτερη προσοχή σε κάθε ανάγκη των πελατών μας. Τοποθετώντας τα μεγέθη ροδέλας ασφάλισης εδράνων στο επίκεντρο, επιτυγχάνουμε συνεργασία με αμοιβαίο όφελος.

Η Jiangsu Swift Machinery Technology Co., Ltd ιδρύθηκε το 2011 και ασχολείται με την ανάπτυξη, την παραγωγή και τη διανομή υψηλής ακρίβειας εξαρτημάτων για εργαλειομηχανές με αριθμητικό έλεγχο. Τα προϊόντα της Swift περιλαμβάνουν ροδέλες ασφάλισης υψηλής ακρίβειας, μονάδες στήριξης διαφόρων βαρών (ελαφρών και βαρέων), συμπεριλαμβανομένων των συστημάτων κινήσεως με ιμάντα και της άμεσης κίνησης, κινητήρες-άξονες, καθώς και άλλα εξαρτήματα υψηλής ακρίβειας. Διαθέτουμε αποθέματα των συνηθισμένων μοντέλων, ενώ μπορούμε επίσης να κατασκευάζουμε και να σχεδιάζουμε προϊόντα σύμφωνα με τις απαιτήσεις των πελατών μας.

Η SWIFT έχει εκσυγχρονίσει τα εργαστήρια κατεργασίας και συναρμολόγησης με ελεγχόμενα μεγέθη για τις ροδέλες ασφάλισης των κουτιών τριβής· έχει εισαγάγει πρωτοποριακό καθολικό γρύπο STUDER, επίπεδο γρύπο OKAMOTO, κατακόρυφο γρύπο TAIYO KOK, κέντρο τόρνευσης και κατεργασίας DOOSAN, μηχάνημα μέτρησης συντεταγμένων ZEISS CMM και μονάδες μέτρησης περιγράμματος και μορφής MAHR. Η πιο πρόσφατη τεχνολογία και η πιστοποίηση ISO 9001 διασφαλίζουν ότι οι πελάτες λαμβάνουν πάντοτε προϊόντα υψηλότατης ποιότητας.

Η ομάδα Έρευνας και Ανάπτυξης καταβάλλει συνεχώς προσπάθειες για τη βελτίωση και τη βελτιστοποίηση των προϊόντων, καθιστώντάς τα πιο αποτελεσματικά και αποδοτικά.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd Πάντα Πάντων Δικαιώματα Ρυθμισμένα - Πολιτική απορρήτου