Have you ever considered how things are created? machines are an essential part of our everyday lives because like creating a lot of things. These possessions can range from toys, furniture, and even automobiles! A special portion of those machinery is a spindle. What are Spindles Used For?Spindles are important as they are responsible for cutting, shaping, and carving different pieces of material, including wood, metal, and plastic.

At SWT, we are thrilled to announce our new 7.5 kW spindle. This powerful tool is very similar to the engine of a car-it gives the energy that is needed to work machines very well and accurately. This spindle allows the equipment to perform quicker and more efficiently. So, let’s go deeper and discover how this incredible 7.5 kW spindle is changing the way we approach machining!

This is a considerable upgrade in the machining world in the shape of a 7.5 kW spindle. This spindle is quite capable of cutting tough materials with its higher power and ever-accurate decimal points. It becomes extremely efficient and smooth the entire manufacturing process. A fast-paced production process allows companies to respond to client requests and meet important deadlines.

One of the most important things about the 7.5 kW spindle is when working it works for a long time without too hot. Production can then continue for hours without requiring stops. It helps businesses save time and money because production runs non-stop. Furthermore, the spindle can operate at high speeds, leading to improved cuts and higher quality finishes for its products. This leads to better quality of work, which is crucial for businesses to retain their customers.

The other significant advantage is the precision of the 7.5 kW spindle. That means that every piece is produced as engineered, which is vital to keeping up product standards. Well-made products are more likely to please customers, who will return to purchase additional products. Upgrading to a 7.5 kW spindle calls for a boost in your credibility, which will naturally bring in greater crowds, ultimately aid you in business growth.

In order for any business to flourish, productivity is the key factor. 7.5 kW spindle allows companies to massively boost productivity numbers. Thanks to this powerful tool, machining processes can take place at significantly shorter periods of time, meaning products can be brought to market more quickly. Production speeding up means businesses will be able to handle orders better and more efficiently meet the demands of customers.

Additionally, the 7.5 kW spindle, which also requires simple operation and maintenance. This minimizes the idle time and allows it to run more frequently thus enhancing the productivity. The spindle gives high-speed capabilities and precise cuts to produce high-quality finishes on products. It adds the additional external worth of spindle to businesses — with a view to making better products for clients.

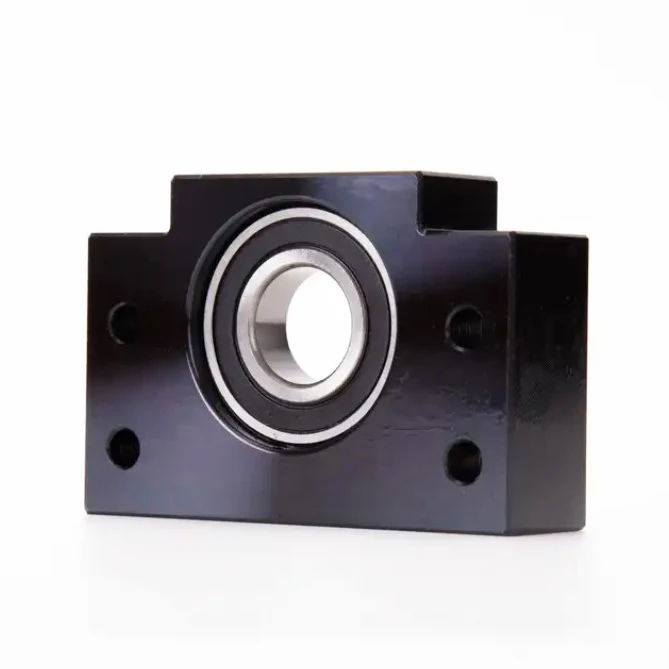

It was established in year 2011. Jiangsu Swift Machinery Technology Co., Ltd specialises creating, manufacturing and selling components that precision for machine tools that use numerical control. Swift's products include precision lock nuts, support units that can handle both heavy light weights including belt drive direct drives, motor spindles as well as other high-precision parts. We provide standard models, however, we can also manufacture and design meet customer's 7.5 kw spindle.

From raw materials finished products, all manufacturing procedures implemented within SWIFT factory. ensures quick 7.5 kw spindle, top quality and competitive price of SWIFT products.With constant efforts of our Research and Developing team, latest technology and innovations are applied to enhance and improve existing products and improve efficiency of our products and efficient.

With decade experience in the industry, SWFIT has good reputation customers from China and around world. 7.5 kw spindleevery customer pay attention to their requirements. place our customers first achieve a win-win cooperation.

SWIFT has modernized temperature-controlled machining assembly workshops has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. customers can be assured 7.5 kw spindlequality products throughout day because our modern equipment as well as ISO9001 certification.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy