Defining Precision in Motion

France’s manufacturing sector has always been synonymous with precision and engineering elegance. When it comes to integral motor spindles—the heart of high-speed CNC machining—the country hosts a mix of established industrial players and agile specialists. These manufacturers don’t just produce components; they enable the entire ecosystem of aerospace, medical, and automotive industries to operate at peak performance. From the Alpine workshops of Grenoble to the industrial corridors of Île-de-France, French spindle makers emphasize innovation, durability, and quiet efficiency. Their products often reflect a tradition of mechanical excellence combined with a forward-looking approach to thermal stability and dynamic balancing.

U-NUT Blending Craft with Technology

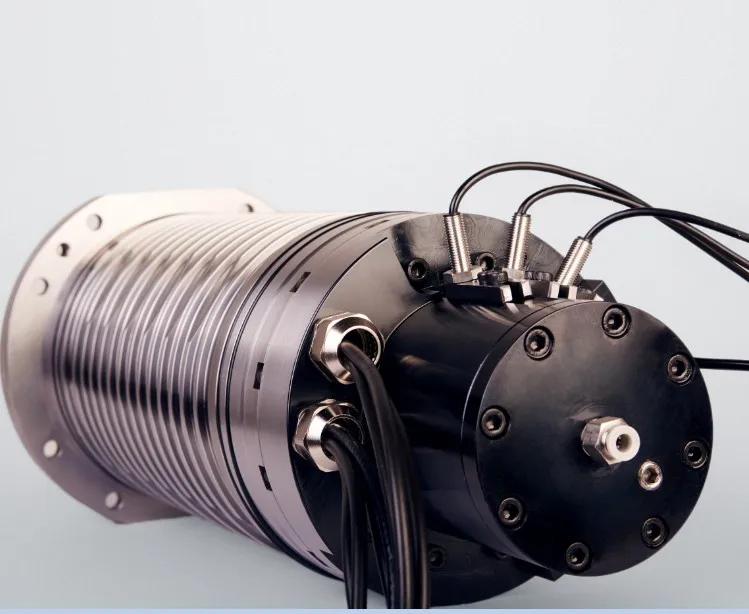

Having spent years in the spindle manufacturing sector, I’ve come to appreciate the subtle differences in design philosophy between regions. French manufacturers, in particular, incorporate a distinct blend of artisanal attention to detail and high-volume technical rigor. Companies like SETCO and Groupe CIF often integrate custom winding techniques and proprietary cooling systems that extend spindle life under heavy use. It’s not just about RPM or power ratings—it’s about how the spindle behaves at the limits of its operational envelope. Vibration damping, for instance, is one area where French engineering stands out. I’ve seen spindles that run quieter and cooler even after hours of continuous duty. That kind of performance doesn’t happen by accident.

Meeting Market Needs with Flexibility

A key strength of the French spindle industry is its adaptability. Whether a client needs a high-torque spindle for heavy milling or a ultra-high-speed unit for fine engraving, manufacturers like LGM and POSA propose solutions that are often tailored in both specs and mounting configurations. We at Jiangsu Swift have collaborated with several European partners, and the French ones particularly impressed us with their willingness to co-design. It’s not just “here’s our catalog”—it’s “tell us your machine’s personality.” That kind of collaboration leads to better products. Also, their after-sales service is usually top-tier, with technical support that actually understands machining contexts.

Challenges and Real-World Performance

Of course, no manufacturing process is flawless. One thing I’ve noticed—especially when auditing spindle performance in the field—is that not all manufacturers are equally transparent about lifespan testing. Some rely heavily on lab data without real-world fatigue simulation. Others, however, like RPS or GTI Spindle, excel in providing honest, data-backed endurance reports. It’s something I wish more buyers would demand. Another thing: thermal growth compensation. Not every French maker gets it right. But the best ones use integrated sensors that actively correct displacement during operation. Little details like that separate the adequate from the exceptional.

Why the French Market Stands Out

What makes France’s spindle manufacturers compelling isn’t just technical—it’s also cultural. There’s a palpable sense of pride in the craft, something that resonates with us at Jiangsu Swift. We operate under similar principles: in-house production, climate-controlled assembly, and a refusal to cut corners on materials. French firms often source their bearings and seals from specialized European suppliers, which adds to consistency. And while they might not always be the cheapest, their products frequently deliver better total cost of ownership. For anyone selecting a spindle partner in France, my advice is simple: look beyond the datasheet. Visit the facility if you can. Ask for runtime logs. The best spindles aren’t just built—they’re validated through use.