Hydraulic cylinder gland nuts are a key component of a working machine and are used to ensure the machine functions correctly. These gland nuts are very important in ensuring that the machines perform their functions properly. In this guide you will understand what a hydraulic cylinder gland nut is the significance of tightening it correctly how it is manufactured and also some useful pointers when replacing a damaged gland nut. We will also look at the various materials used to make gland nuts and why those materials are important.

This hydraulic lock nut A small but very vital part of a hydraulic cylinder which is a crucial part of a lot of machines. Its primary function is to contain the hydraulic fluid within the cylinder and prevent it from escaping. So it is a crucial component because the hydraulic fluid allows the machine to accelerate and do the work. If because the gland nut does not does a good job make the machine can not be used properly you can also lead to problem. If there is a leak for example the SWT machine might stop moving or work less efficiently.

Proper torque of the SWT cylinder gland nut is critical. If the nut is too loose the hydraulic fluid can leak out this causing the machine to work poorly or not work at all. This is annoying and can eventually even cause expensive repairs. However, over tightening the nut will break or damage the hydraulic nut. This can make it extremely difficult to pull the nut when it needs replaced, which only leads to further problems.

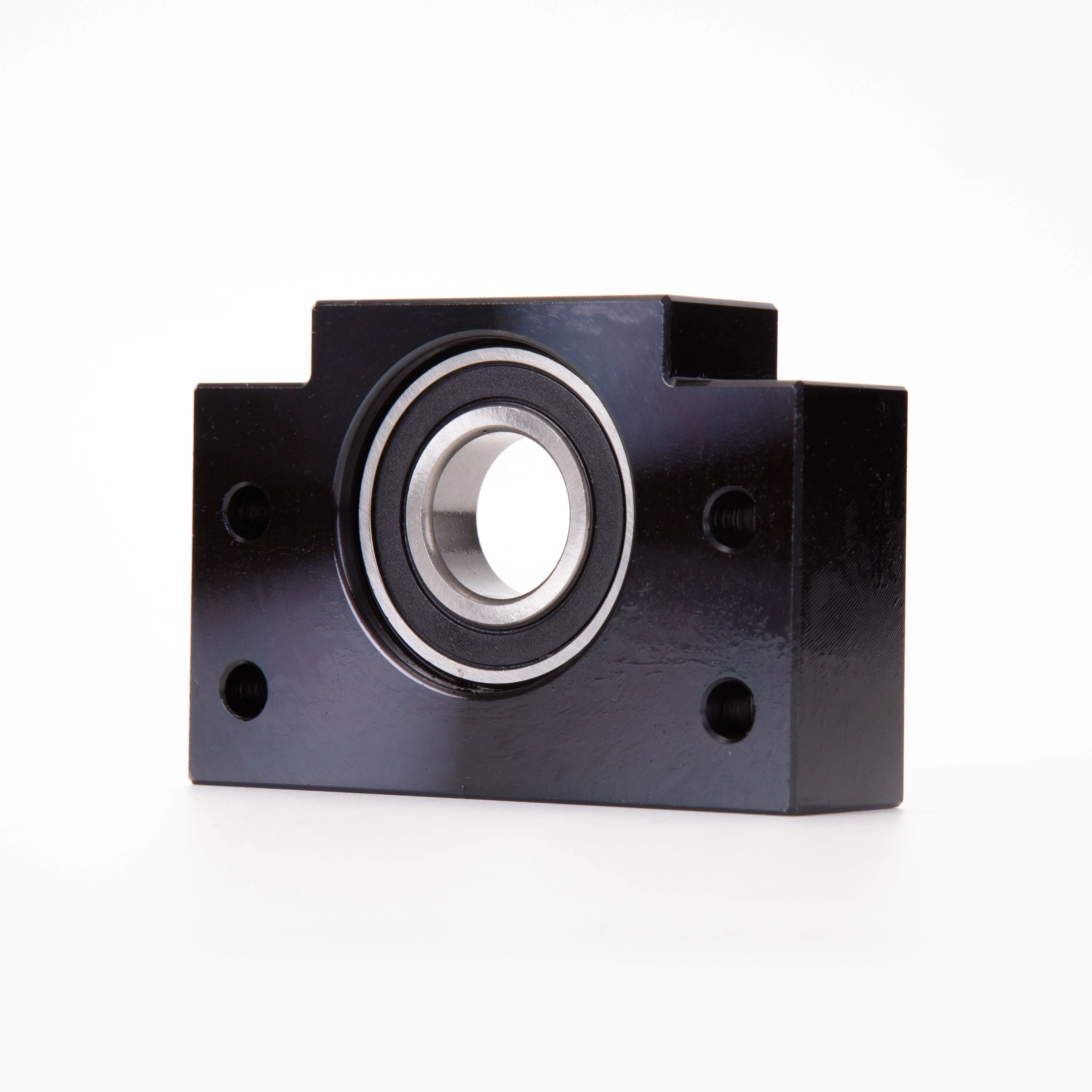

Typically, SWT hydraulic cylinder gland nuts are constructed from durable metals, such as aluminum or steel. This is why these materials are durable, they can take a lot of pressure. The gland nut has internal threads allowing it to be tightly screwed onto the hydraulic cylinder. Some glands seal extra, like a type of rubber or plastic inside. This mechanism further reduces the possibility of leaks. The design of the hydraulic nut seems simple, but it is ingenious and well thought out, enabling it to do its job fully.

Hydraulic Cylinder Gland Nut Replacement If a hydraulic cylinder gland nut is broken or worn out over time, you should replace it right away. If replacement is not done, it can make trouble for the machine. The cable gland nut is a component that can be removed and replaced. You should do this gently, so you don’t end up breaking something else. You will then remove the old gland nut and screw on the new one. Therefore, it is extremely critical that you follow the instructions and tighten it properly. It is always advisable to check it for leaking around the new nut after replacing the gland nut to avoid any problems and to be sure it is working fine.

Following is the information that you need to know when selecting materials for a hydraulic cylinder gland nut according to a machine. The type of environment the machine will operate in also counts. Gland nuts are often made out of steel and aluminum since these materials are often robust and can last long. But there are also materials like brass or plastic which may be better suited for the needs of the machine. Machines that need to be lightweight could use a plastic gland nut for example to do a better job.

SWFIT has great reputation China as well as other countries. value every client and pay great deal attention to each every need of our clients. Put Hydraulic cylinder gland nutat center achieve a win-win cooperation.

SWIFT has modernized temperature-controlled machining assembly workshops and has Hydraulic cylinder gland nuttop-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. latest technology and ISO9001 certification ensure our clients will receive highest quality products every time.

It was established the year 2011. Jiangsu Swift Machinery Technology Co., Ltd is specialist in creating, manufacturing selling high-quality components for numerical control machine tools. Swift products include precision lock nuts, support units both heavy light load, belt drive, direct drive spindles for motors and lathes, other high-precision parts. We offer standard Hydraulic cylinder gland nutbut also can manufacture design to meet customer's specifications.

Research and Development team always striving improve and Hydraulic cylinder gland nutproducts make them more efficient effective.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy