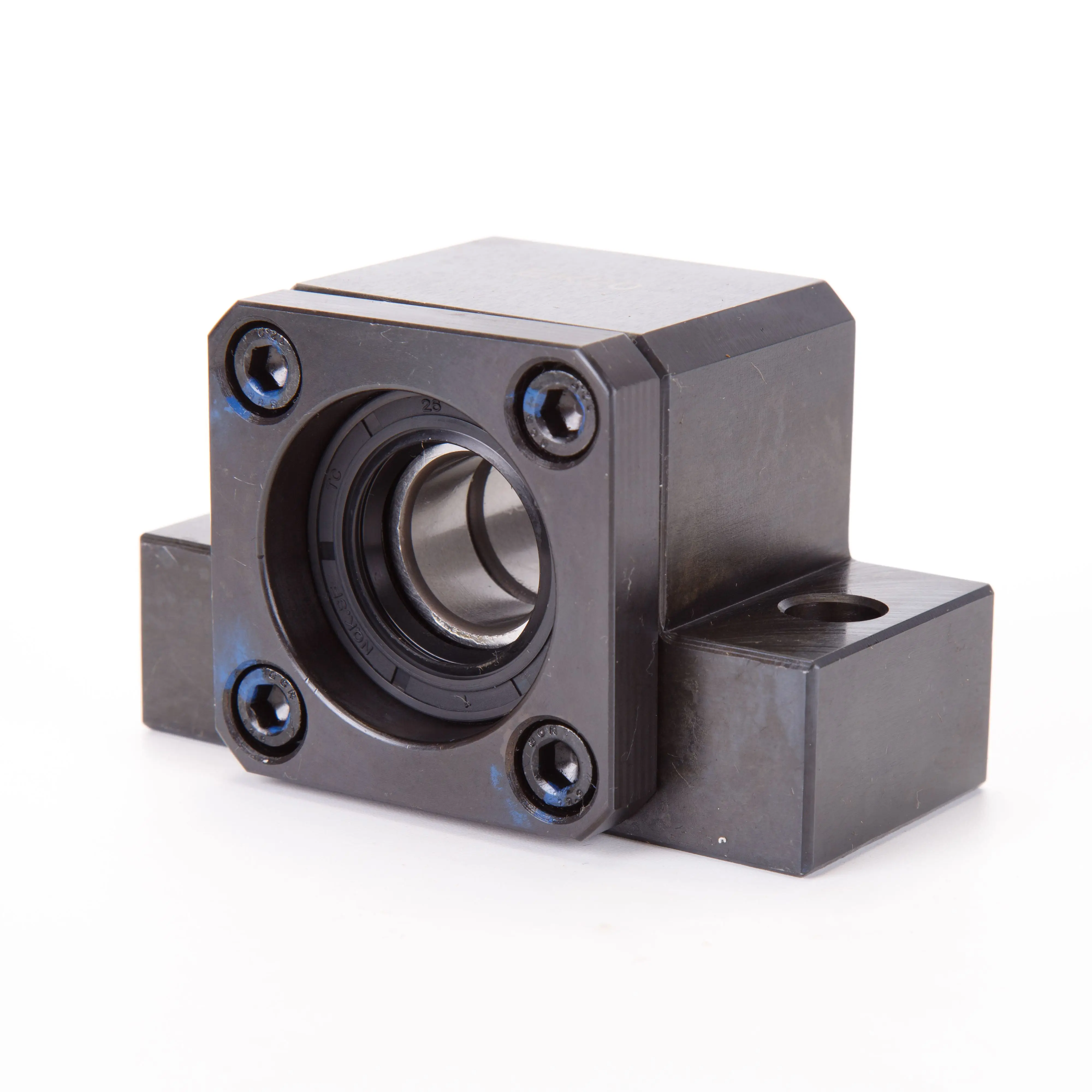

A ball screw bearing block is a key part of machinery to keep movement bit smooth and precise. It is important to maintain it to keep the machine running smoothly and to enhance performance. When it comes to selecting a ball screw bearing block, there are a few main factors you should take into account so that you can get the most efficiency and performance out of your application.

The ball screw bearing support is a key element of a ball screw system. It functions as a stand for the ball screw and enables smooth and precise movement of the ball screw. The bearing block guides the ball screw and holds it in position while the ball screw assembly is in motion. If a bearing frame is not used, a ball screw may not run properly and performance of the machine may well be low.

Ball screw bearing block is of great significance in achieving motion accuracy and smoothness of machinery. It can decrease the ball screw and the machine friction, noise and the vibration. With high speed, high precision, long life, high rigidity, high temperature, low temperature, high speed and torque. This is advantageous in that better defectiveness and working efficiency of the machine is obtained. What´s more, the machine may move hoarse and inaccurately, which results in production loss due to the poor bearing block.

When selecting a ball screw bearing block there are several important factors to consider. One consideration is the type of bearing block material. The material from which it is made needs to be sturdy enough to take the wear and tear of constant use. The size of a bearing block to be used is another consideration, as this should be compatible with the ball screw size. Also, the bearing block must be capable of the load on and pressure exerted on it during use.

You can improve the efficiency and performance of your device by selecting the appropriate ball screw bearing block. A good bearing block can lower the friction, improve work efficiency and accuracy. It will also prolong the service life of the equipment and reduce the frequency of maintenance. A quality bearing block is necessary for keeping your machines working at their best.

Ball screw bearing blocks must be well maintained and lubricated to guarantee their lifespan and the performance. Preventive maintenance can prevent the damage or more time service life. Besides, lubrication will also lessen friction and maintain the ball screw performing at maximum efficiency. Simply maintain your bearing block and adhere to the manufaturer's recommended maintenance, so your machine can run smoothly and be used for many years.

From material to finished products, all production procedures executed within SWIFT factory. ball screw bearing block quick delivery, super quality and competitive prices of SWIFT products.With continual efforts of our Research and Developing team, new technology and concepts applied to optimize and improve existing products and improve the efficiency of products and efficient.

SWIFT modernized temperature-controlled machining assembly workshops and has imported top-leveled STUDER universal grinding machine, OKAMOTO Surface Grinder, TAIYO KOK vertical grinding machine, DOOSAN turning center machining center, ZEISS CMM, MAHR contour form measuring units. latest technology ISO9001 certification ensure that customers will receive the most reliable equipment throughout day.

Jiangsu Swift Machinery Technology Co., Ltd founded in 2011 and has focus on the design, ball screw bearing blockand sales precision components used in numerical-control machine tools. Swift products are precision lock nuts, support units that both light and heavy load belt drive, direct drive spindles for motors and lathes, other high-precision parts. stock our regular models as well as create manufacture according to the requirements of customers.

With over ten years experience in the industry, SWFIT has good ball screw bearing blockits clients in China as well as overseas. cherish every customer attach great importance to the needs of each customer. Customers at the heart of our company. We work hard create an environment that is win-win everyone.

Copyright © Jiangsu Swift Machinery Technology Co., Ltd All Rights Reserved - Privacy Policy